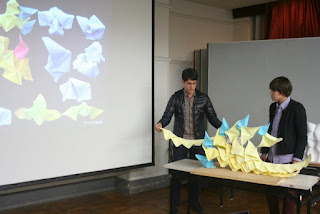

While our 1st year students are exploring the topic of customisable mass production processes based on the logic of evolutionary development, our 2nd year students are continuing to work on their Cybernetic Urbanism project. The main objective of this studio project is to develop an artificial life-like urban ecology integrating natural and human environments via biological and industrial processes.

Here are videos of their earlier projects posted on TUESDAY, 5 JULY 2011.

Another work-in-progress video from our current studio. Team Oil Killer is developing an architectural prototype that made of recycled crude oil collected from an oil spill site, which would then function as both energy storage (solidified crude oil) as well as building materials for creating a public space for a local community. The main material used for the project is human hair, also recycled, acting as an oil absolving matt. Once the matt is saturated with the oil, it is taken out of the water and then solidified to become a roof structure, which can be disassembled when required as energy supply for an emergency situation caused by a natural disaster. The project also challenges the conventional oil storage facilities in an urban context by turning inaccessible industrial territories into a potential public space while maintaining its function as energy storage.

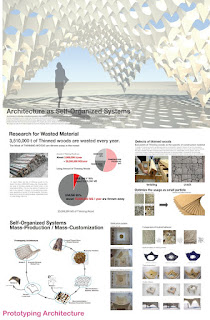

This video shows the current state of our Stick team’s project. Their ambition is to develop a manufacturing system that integrates the potential of mass-production, which optimises efficiency in terms of the amount of material and production time, and the logic of mass-customisation, which maximises the possible variations in terms of formal outputs. Their project explores the issue of discarded logs in forests in Japan. Due to the increase in cheap lumbers being imported from Europe and North America, Japanese forest industry has lost its grip on competitive global lumber markets. As a result, many forests have now become abandoned causing problems for both their economy and ecosystem. The project also aims to bridge a link between Japan’s wood working traditions and computational fabrication techniques.

This project is built on Frei Otto’s experiment on Form-Finding, which is a formal and structural optimisation process based on material’s inherent distributional logic.