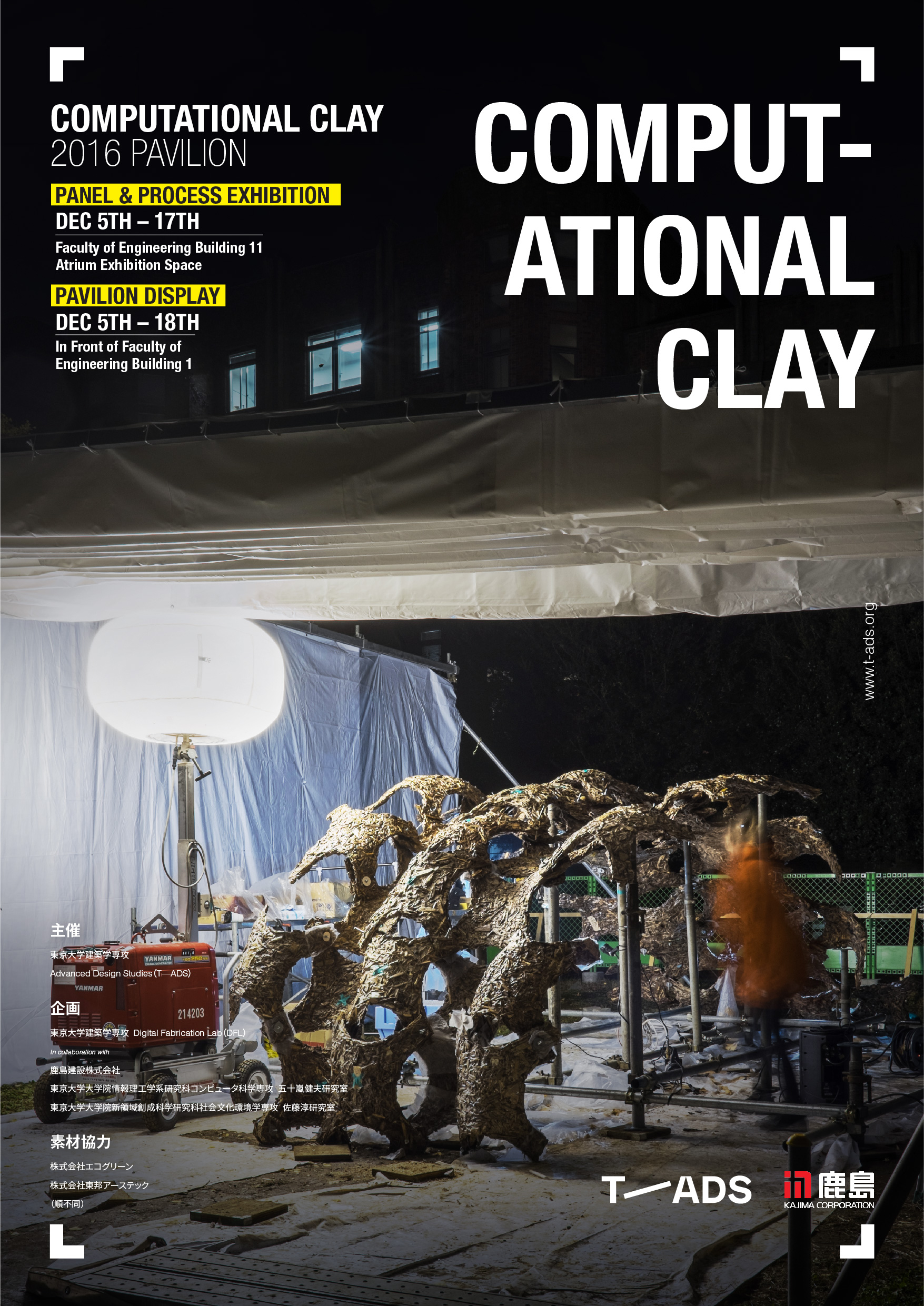

パビリオン公開 // PAVILION DISPLAY

12月5日(月)– 12月18日(日)// December 5 (Mon) – December 18 (Sun)

10:00 – 17:00

東京大学本郷キャンパス工学部1号館前広場

The University of Tokyo, Hongo Campus, Engineering Building #1 Plaza

パネル・模型展示 // PANEL AND PROCESS EXHIBITION

12月5日(月)– 12月17日(土)// December 5 (Mon) – December 17 (Sat)

平日と土曜日のみ // Weekdays and Saturdays only

(12月5日は13:00から) // (Open at 13:00 on December 5)

東京大学本郷キャンパス工学部 11 号館1階展示スペース(入場無料)

The University of Tokyo Hongo Campus, Engineering Building #11, 1F Exhibition Space (free entry)

主催: 東京大学建築学専攻 Advanced Design Studies(T—ADS)

PRODUCED BY: Advanced Design Studies, Department of Architecture, The University of Tokyo

企画: 東京大学建築学専攻 Digital Fabrication Lab(DFL)

鹿島建設株式会社

東京大学大学院情報理工学系研究科コンピュータ科学専攻 五十嵐健夫研究室

東京大学大学院新領域創成科学研究科社会文化環境学専攻 佐藤淳研究室

素材協力: 株式会社エコグリーン、株式会社東邦アーステック(順不同)

PLANNING:

Digital Fabrication Lab (DFL), Department of Architecture, The University of Tokyo

IN COLLABORATION WITH:

Kajima Corporation

Graduate School of Information Science and Technology, Department of Computer Science, Takeo Igarashi Laboratory

Graduate School of Frontier Sciences, Department Socio-cultural Environmental Studies, Jun Sato Laboratory

MATERIALS PROVIDED BY:

Eco Green, Toho EarthTech (in random order)

東京大学建築学専攻Digital Fabrication Lab(DFL)では、建築施工におけるデジタル技術の活用をテーマに、毎年実験的なパビリオンを制作しています。単に技術による自動化や高度化を目指すのではなく、そこに「人間が関わること」の可能性を探る実証の場として、これまで「人間と機械が融合した3Dプリンター」(2014年STIKパビリオン)や「巨大3Dペン」(2015年TOCAパビリオン)を建築スケールで再現してきました。

本年Computational Clayプロジェクトでは「人間が関わること」をより一層推し進め、個性としての身体パフォーマンスを建築表現に反映させるため、人の動きと素材と関係に着目したユニークなパネル加工システムを開発しました。

Every year in the University of Tokyo’s Digital Fabrication Lab (DFL), digital fabrication technologies are used to produce an experimental pavilion project. The aim, rather than being simply to achieve automation or precision through use of such technologies, is to explore the potentials for human and machine collaboration. Past projects have focused on fusions between humans and machines through the use of 3D printers: the 2014 STIK Pavilion explored this theme through guided aggregation, and the 2015 TOCA Pavilion by using humans as a parameter along with an oversized 3D pen.

This year, in the Computational Clay Pavilion, we advance the role of the human in construction one step further, examining how an individual’s capabilities and performance can be expressed in an architectural output. We have developed a unique panelized construction system wherein the movements of humans and their relationship to the material are explored.

Photos by Veronika Smetanina.

Photos by Veronika Smetanina.