If you find yourself being around Todai Hongo campus, please come and visit our exhibition!

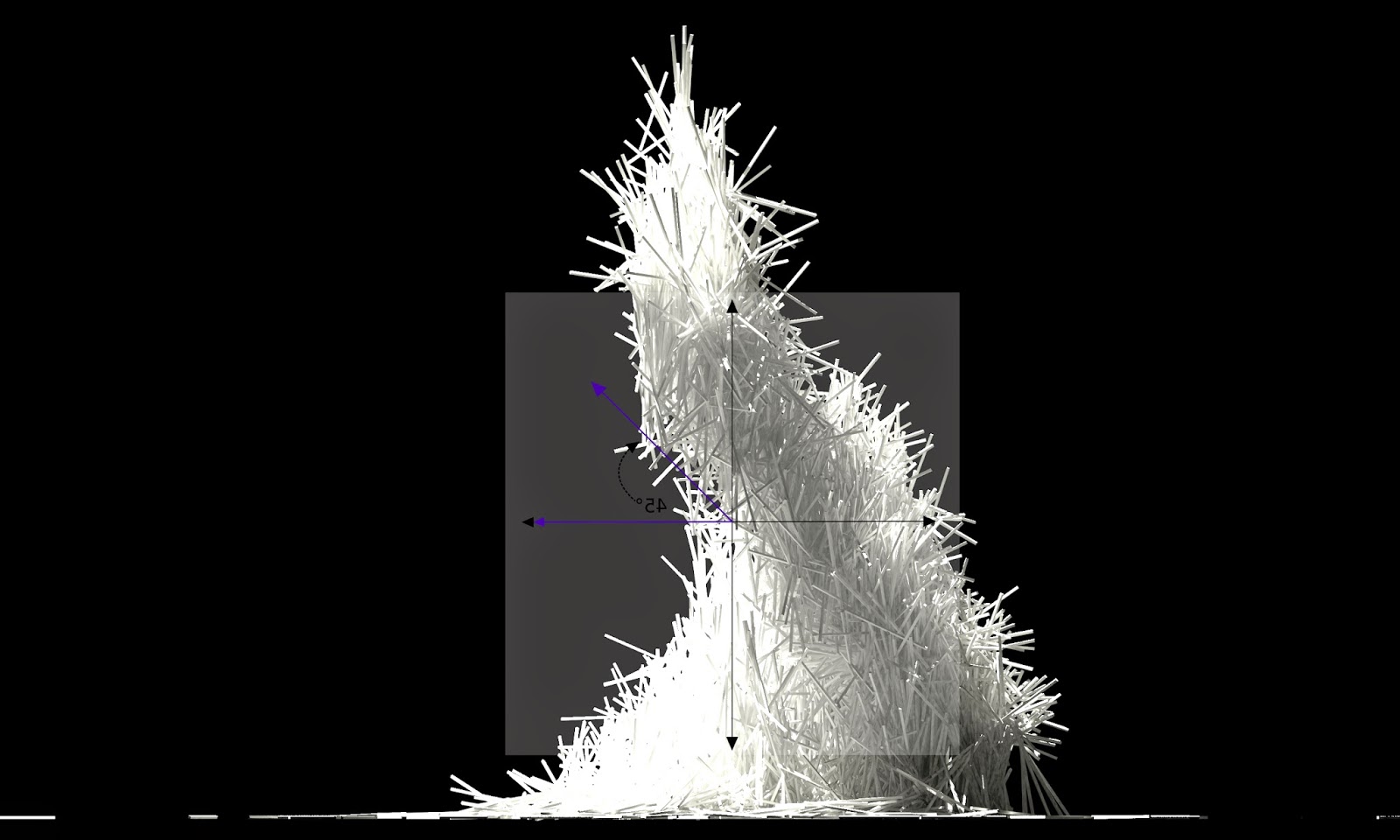

With the advancement of technology, data has become readily available and easy to produce, while material resources and traditional craft are disappearing from our contemporary life. With Japan’s declining population, skilled labor in the building sector is projected to be insufficient to maintain and produce the architecture of the future with quality that Japan is known for. Thus, our approach is to integrate Information distribution technologies with human tasks. We seek to utilize methods of human augmentation to create a dynamic system of distributed 3D printers capable of “printing” a large-scale, on-site, formwork-less structure.

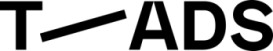

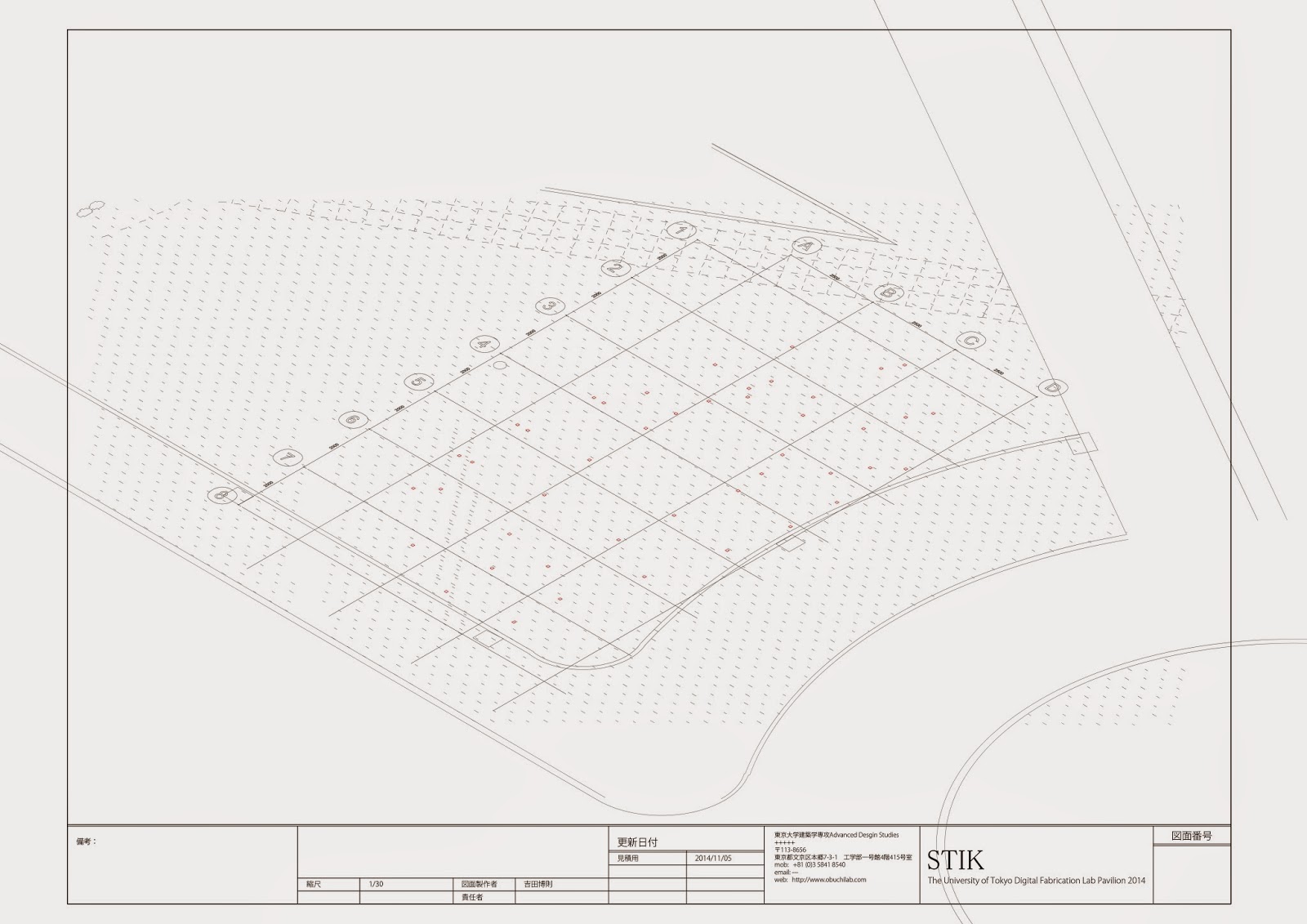

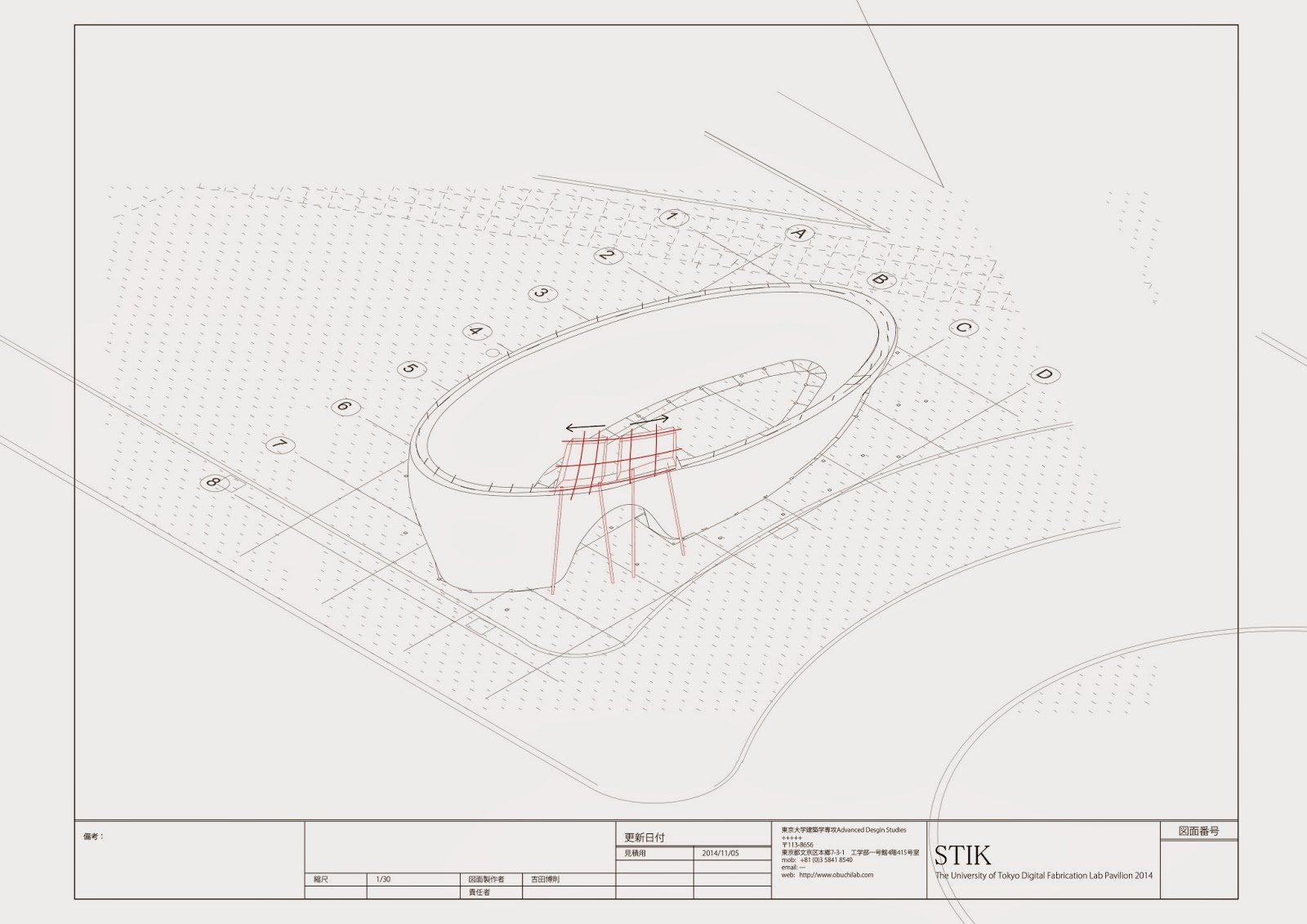

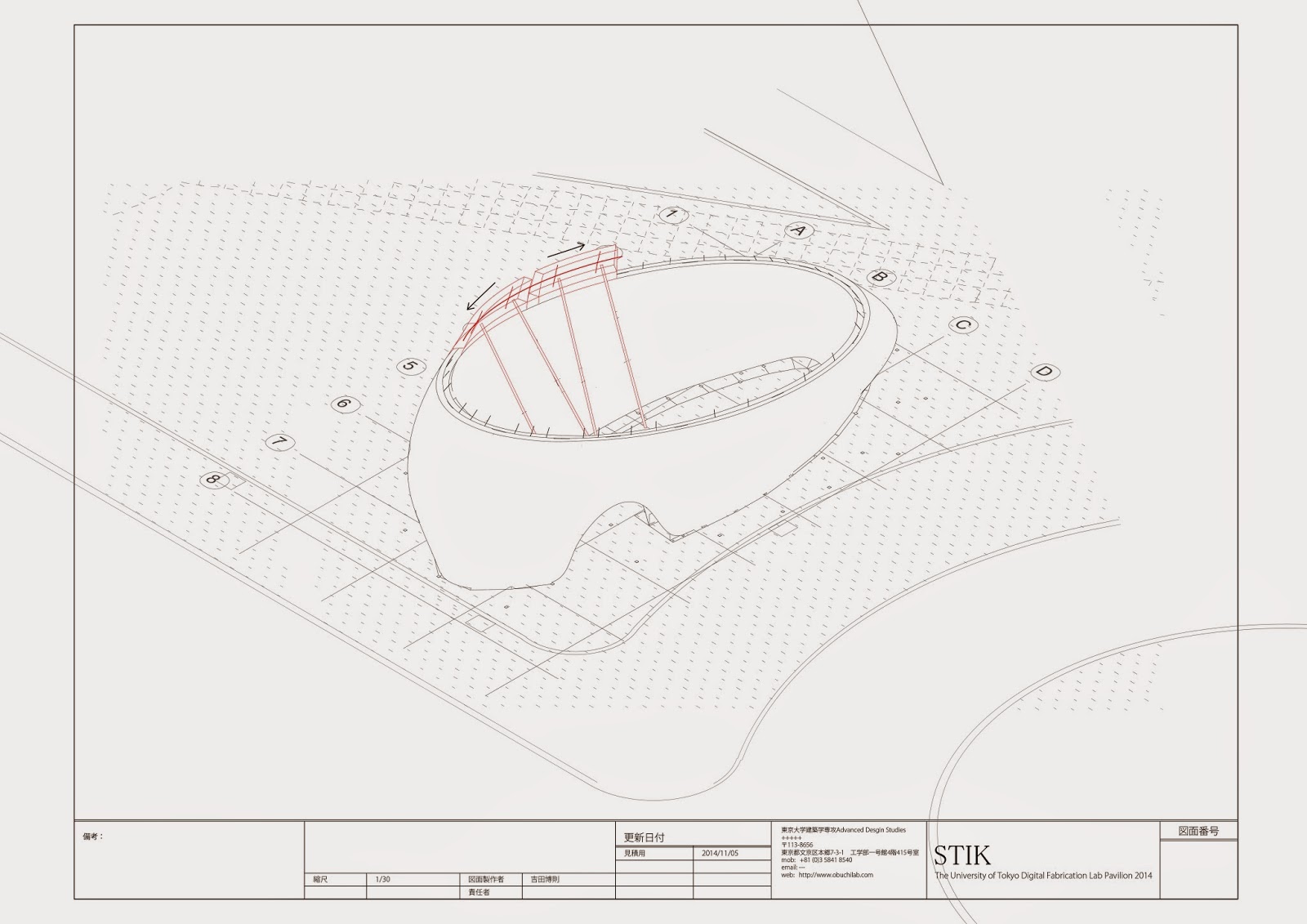

Our proposal is a network of human-driven 3D printing devices, which we call STIK (Smart Tool Integrated Konstruction). The basic component for the system is a chopstick, ‘waribashi’ which is a recycled material collected from an industrial chopstick production process. By controlling the way that these sticks are locally distributed, we can aggregate them into a specific geometry that is inherently stable. A scanning system monitors the printing process, sending data to the network, which is compared to the overall digital target geometry. The network then feeds back to each distribution node, controlling the progress of the structure.