Advanced Design Studies Blog: Critical Mass

Critical Mass Posts

The construction of our food cart project in Commune 246 now get started! YES!! We designed our food cart to be wrapped by Cast-On-Site Chopstick finishes, which fabrication system has been developed by our Digital Fabrication Lab at T_ADS in collaboration with Shimizu Corporation. Now we completed an assembly of main wooden structures capped by a roof steel frame with transparent tent roof on it. We will start soon the Chopstick casting phase!

A sectional animation through a wall of the pavilion. The internal aggregation of the sticks can be analysed.

STIK Internal Structure from Obuchi Lab at UnivTokyo on Vimeo.

Today we scanned the pavilion to check how accurate we have been while installing the STIK panels. We have used both traditional methods of checking the accuracy, as well as a projection / scanning system while placing the panels. The construction process has largely been driven by our research into computer scanning and projection methods. We found that our process has been quite accurate to date.

If you find yourself being around Todai Hongo campus, please come and visit our exhibition!

Few words about the exhibited project:

At the Advanced Design Studies’ Digital Fabrication Lab, we have been exploring methods of integrating computational design with construction processes.

With the advancement of technology, data has become readily available and easy to produce, while material resources and traditional craft are disappearing from our contemporary life. With Japan’s declining population, skilled labor in the building sector is projected to be insufficient to maintain and produce the architecture of the future with quality that Japan is known for. Thus, our approach is to integrate Information distribution technologies with human tasks. We seek to utilize methods of human augmentation to create a dynamic system of distributed 3D printers capable of “printing” a large-scale, on-site, formwork-less structure.

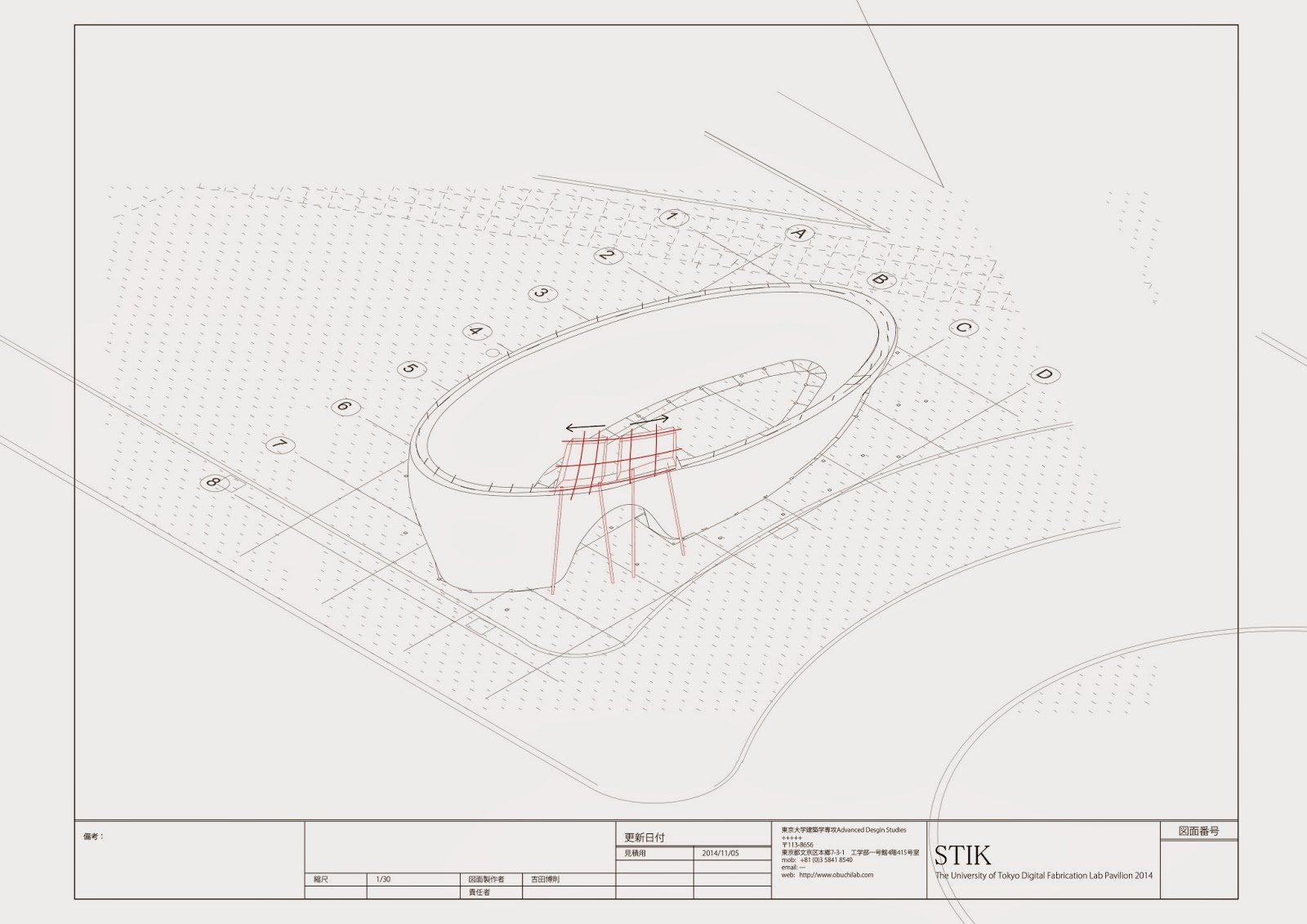

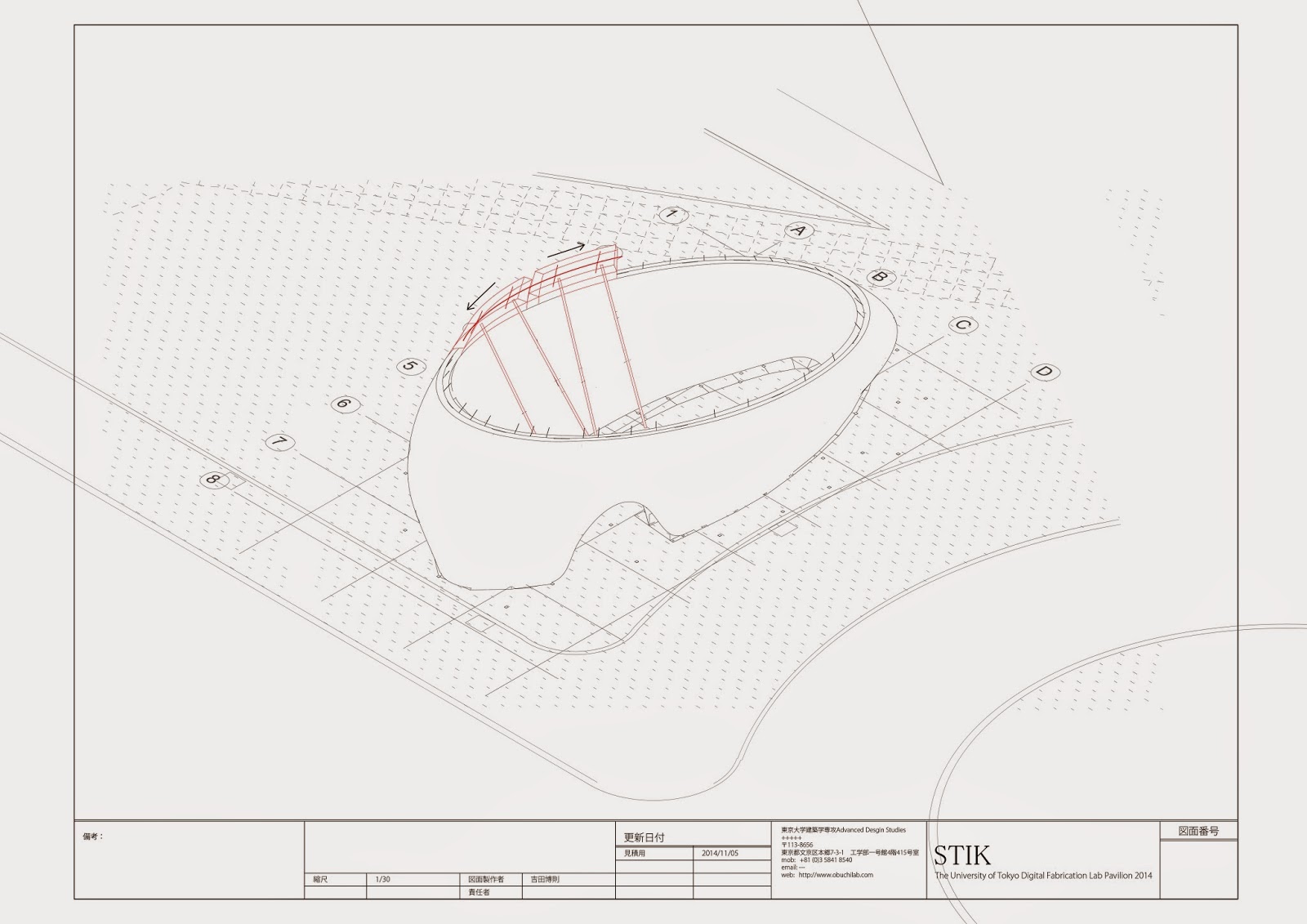

Our proposal is a network of human-driven 3D printing devices, which we call STIK (Smart Tool Integrated Konstruction). The basic component for the system is a chopstick, ‘waribashi’ which is a recycled material collected from an industrial chopstick production process. By controlling the way that these sticks are locally distributed, we can aggregate them into a specific geometry that is inherently stable. A scanning system monitors the printing process, sending data to the network, which is compared to the overall digital target geometry. The network then feeds back to each distribution node, controlling the progress of the structure.

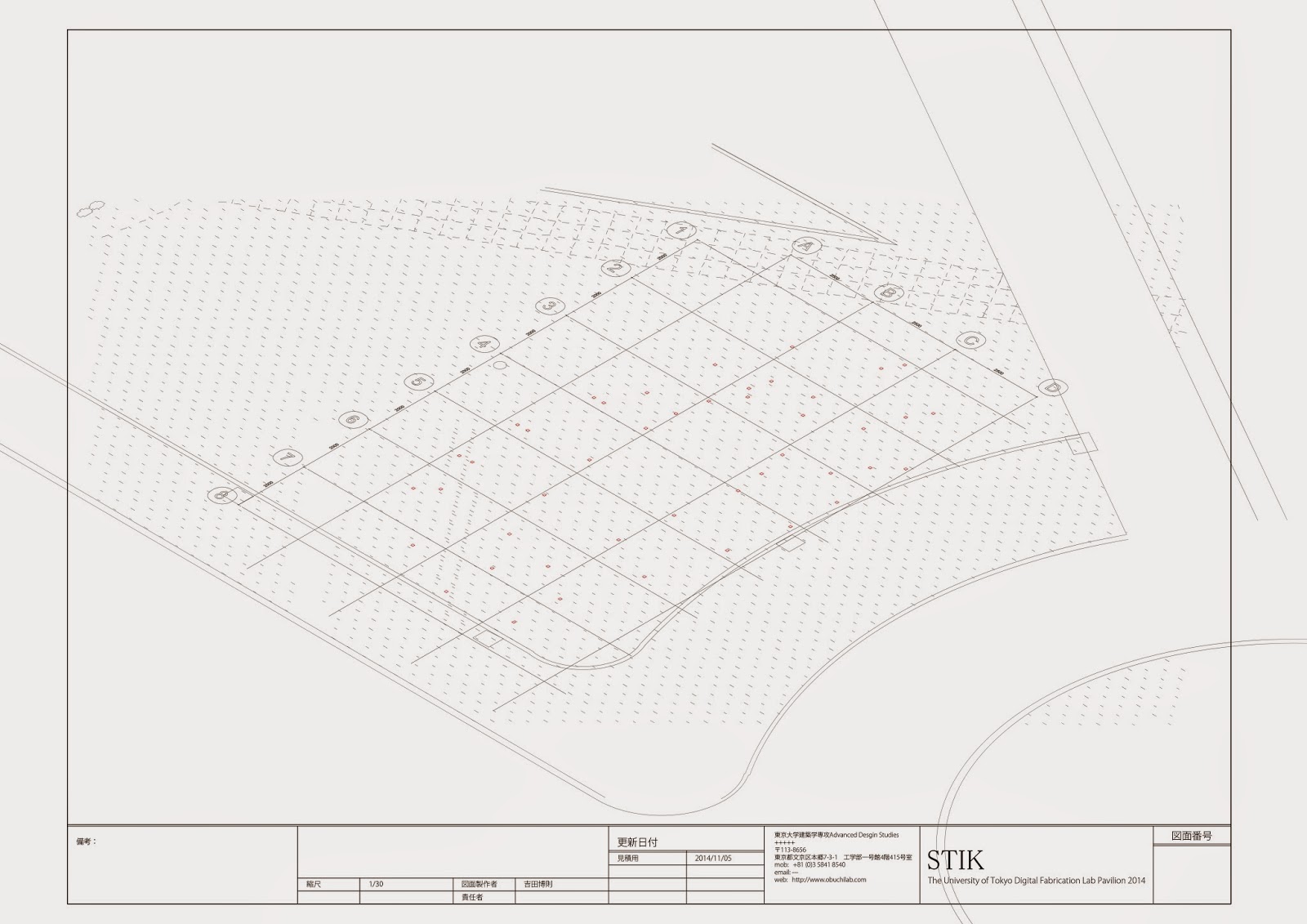

We are utilizing / experimenting with a hybrid method of in-situ and panelization of the STIK system in order to construct the pavilion. The diagrams below illustrate the process we are currently working through in putting together the construct.

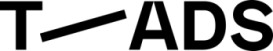

Placement of markers on the site.

Placement of plywood base panels

Installation of foundation modules

Installation of the entrance and side-boards

Placement of concrete anchoring blocks

In-Situ pouring of Row A utilizing our scanning system

Placement of prefabricated Row B panels

Bracing of Row B panels

Complete placement of Row B panels

Infill around Row B panels

Placement of prefabricated Row C panels

Complete placement of Row C panels

Placement of prefabricated Row D panels

Completion of Pavilion