Press release Embassy of Switzerland in Japan, 14.07.2022

A collaborative program of Aichi Trienniale 2022

July 30 to October 10, 2022At the Tokoname City Pottery Footpath (Sakae-cho 7-chome, Tokoname-shi, Aichi)

Switzerland and Japan explore the future of architecture at Aichi Triennale 2022! Kizuki-au 築き合う— Collaborative Constructions consists of two installations by Gramazio Kohler Research from ETH Zurich and T_ADS Obuchi Lab from the University of Tokyo. The project sheds light on digital processes in architecture, human-robot interactions and cross-pollination between technology and culture.

Our globalised societies have entered into a new phase. The pandemic has revealed how our communities are intricately linked beyond national borders, in a world that has become more fragile. At the same time, the widespread popularization of online communication demonstrates how technology is helping to re-connect in times of forced isolation; we can talk to anyone, anywhere, almost anytime. In this emerging order, we ask how architecture can reimagine its own tradition and role in society.

Collaborative Constructions investigates a new practice of architecture based on the creative, innovative and personal use of technology. The two projects by ETH Zurich and the University of Tokyo engage in a global collaboration looking at architectural strategies to relate nature and humanity through technology; they are results of human-robots collaborations and exemplify how we can engage with the past while looking ahead.

The project by Gramazio Kohler Research from ETH Zurich in Switzerland is a three-storey all-timber frame structure, which revives the long history of expert timber construction in Japan through Swiss design and technology. It revisits carpentry for the age of robotics, making metal parts, nails, screws or fasteners obsolete. The five constituting timber frame modules consist of more than a thousand bespoke timber elements and were prefabricated in the world-renowned Robotic Fabrication Laboratory at ETH Zurich. Designed to withstand earthquakes and storms, it is a towering structure, which activates its surrounding neighbourhood and landscape, while the wooden terrace or Japanese engawa serves as a meeting point for the community. Age-old knowledge has been revived through digital technologies, allowing for a highly material efficient and performative approach to building with timber. A new strategy for building multi-storey timber buildings is thus suggested as a sustainable alternative to conventional concrete and steel constructions.

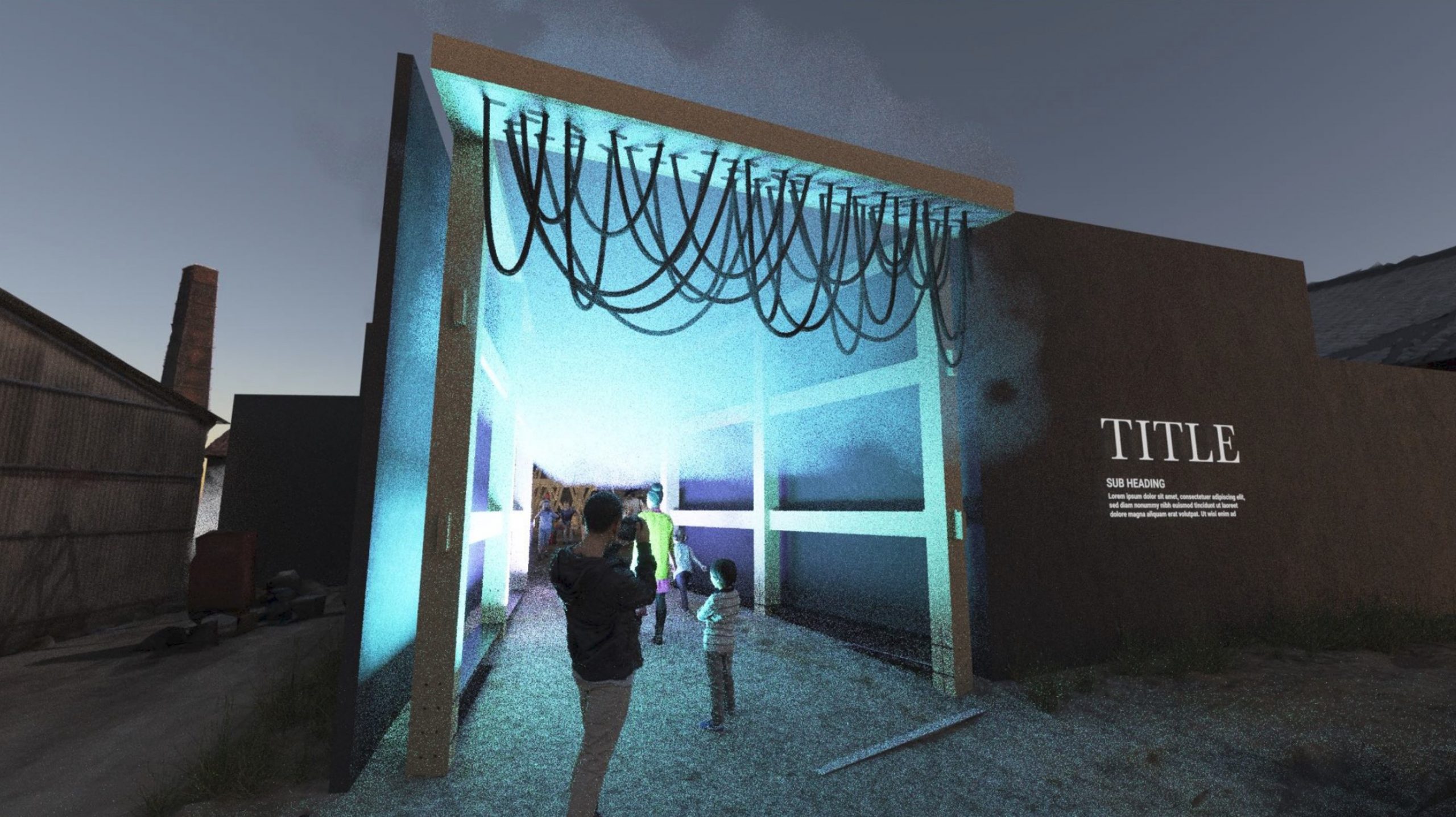

The project by T_ADS Obuchi Lab from the University of Tokyo is a gate-like structure made of wooden posts and beams, serving as an entrance to the courtyard surrounded by an old pottery factory. A series of pottery chains hanging from the gate’s beams form a large screen and resemble a traditional noren. It is a visual sign to welcome the visitors as well as an evaporative cooler, a natural climate control, in which mist dampens the surfaces of the pottery. On a hot day, the evaporative cooling effect of the pottery is expected to cool the gate area by 4 to 5 degrees Celsius.

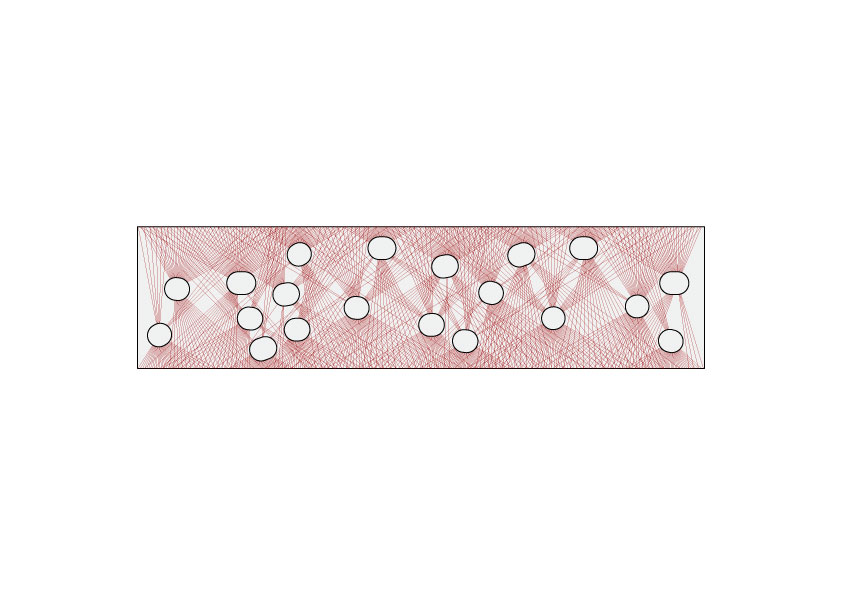

At the heart of the project is the fabrication of the hanging pottery chains. While the pattern appears to be random at first glance, its generation requires an intricate algorithm, an algorithm that brings human and machine together. The pottery chains are created by a series of feedback processes between a person and a robot. Each person makes a uniquely defined shape of pottery chain by holding it so that it hangs from their arms without touching the ground. The robot then finds a location on the beam for its installation within the given dimension of the beam and structural requirements. The final design of the overall patterns, made of forty-five of the hanging chains, are generated by children and adults with different physiques and strength reflecting their individuality into the whole.

Faced with the post-industrial legacy of Tokoname, the collaboration between ETH Zürich and the University of Tokyo reimagines the place through an extended notion of empathy: its people, traditions, history, environment and culture are all intertwined and made tangible through digital processes in fabrication and construction. Architecture becomes a form of living knowledge, an expression of being alive.

Collaborative Constructions is an initiative of the Embassy of Switzerland in Japan, ETH Zurich and the University of Tokyo, in collaboration with Shimizu Corporation. The project is part of Vitality.Swiss, Switzerland’s program on the road to Expo 2025 Osaka-Kansai.

Kizuki-au 築き合う-Collaborative Constructions

Period July 30 to October 10, 2022 Open time 11:00 – 19:00Venue 79, 80, 83, 84, Sakae-cho 7-chome, Tokoname-shi, Aichi, JapanFree of chargeMore info. www.vitality.swiss

OrganizersEmbassy of Switzerland in Japan / Vitality.SwissGramazio Kohler Research, ETH ZurichT_ADS Yusuke Obuchi Laboratory, Department of Architecture, Graduate School of Engineering, The University of Tokyo

Project CollaboratorShimizu Corporation

PartnersIWC SchaffhausenBMW Japan

Panasonic Holdings Corporation

LIXIL CorporationERNE AG BauunternehmungCypress Sunadaya Co., Ltd.VitraJun Sato Laboratory, Department of Socio-Cultural Environmental Studies, Graduate School of Frontier Sciences, The University of TokyoKalt Maschinenbau AGSJB Kempter Fitze AGKnapp AGRaimund BECK KG

MONTAGE Inc.Tokoname CityThe University of Tokyo, Strategic Partnerships Project

State Secretariat for Education, Research and Innovation SERIFDFA, Presence Switzerland

Kizuki-au、築き合う– Collaborative Constructions

Our globalised societies have entered a new phase. The pandemic has revealed how our communities are intricately linked beyond borders and how mutually dependent we are in an evermore fragile world. Meanwhile, the popularization of online communication demonstrates how technology helps us re-connect even in forced isolation; we could talk to anyone, anywhere, anytime. In this emerging order, how can architecture reimagine its tradition and role in society?

Collaborative Constructions investigates a new practice of architecture based on the creative, innovative and personal use of technology. The projects by Gramazio Kohler Research at ETH Zurich, and T_ADS Obuchi Lab of the University of Tokyo engage in a collaboration seeking architectural strategies to relate nature and humanity through technology; human-robot collaborations exemplify how we can engage with the past while looking ahead.

The project reimagines Tokoname with its post-industrial legacy, through an extended notion of empathy: its people, traditions, history, environment and culture are intertwined and made tangible through digital fabrication. Architecture becomes an expression of being alive.

The project is an initiative of the Embassy of Switzerland in Japan, ETH Zurich and the University of Tokyo, in collaboration with Shimizu Corp. It is part of the Vitality.Swiss program.

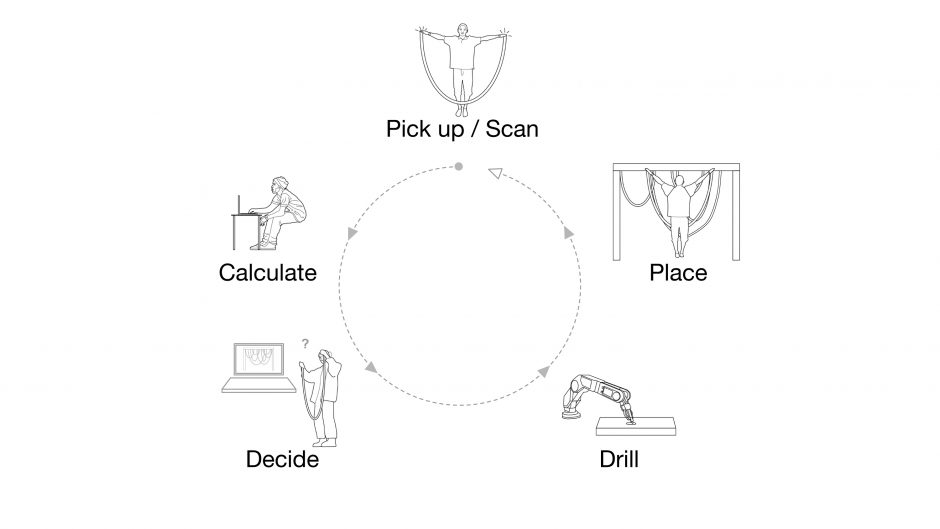

Participatory Shape Generation

Each person makes a uniquely defined shape of pottery chain by holding it with different physiques and strengths reflecting their individuality.

Real-time Optimization

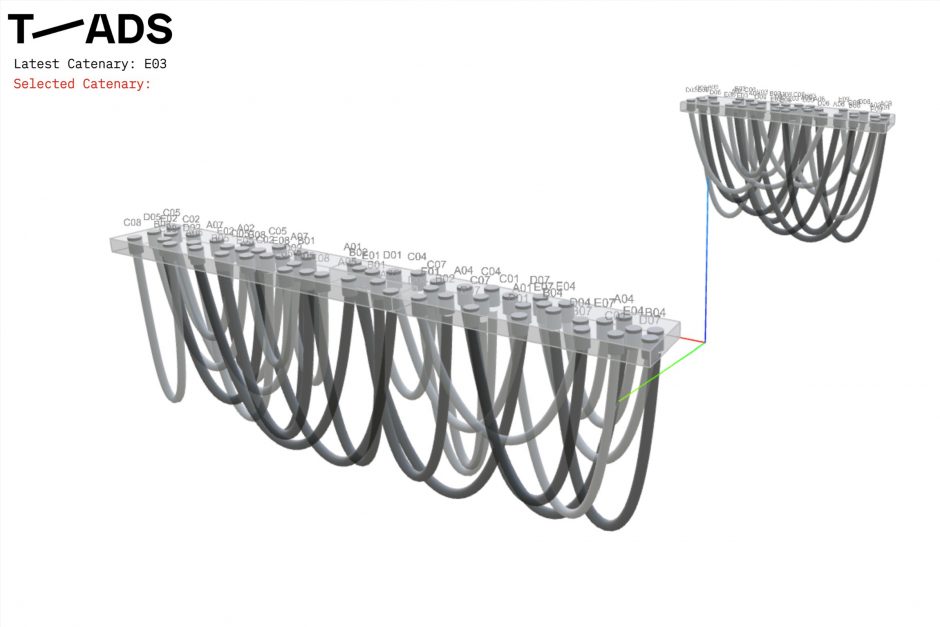

The heart of the project is the fabrication of the hanging pottery chains. While the pattern appears to be random at first glance, its generation requires an intricate algorithm, an algorithm that brings humans and machines together.

Robotic Drilling

“Collaborative Constructions” combines elements of traditional architectural construction, culture, and natural materials with modern digital technologies such as computational design and robotics fabrication.

Collaborative Constructions

Process Chronology

Human Scaled Participatory Shape Generation

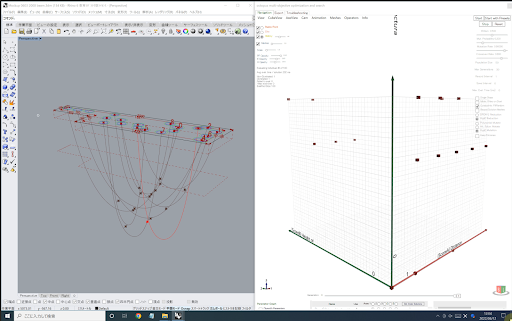

The pottery chains are created by a series of feedback processes between a person and a robot. The pottery chains are created by a series of feedback processes between a person and a robot. Sensors are placed on each subject’s hand so that the information-gathering process is as natural as possible.

Real-time Optimization Controlling Design Outcome

Optimization Criteria

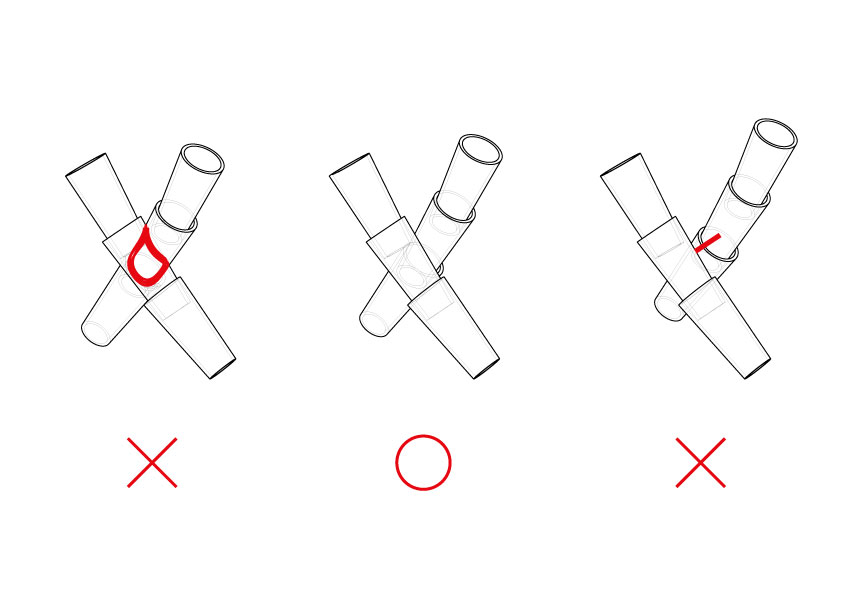

Tangential Connections

Distance between catenaries should be within a certain domain to avoid intersection, but meanwhile should allow to be tied together.

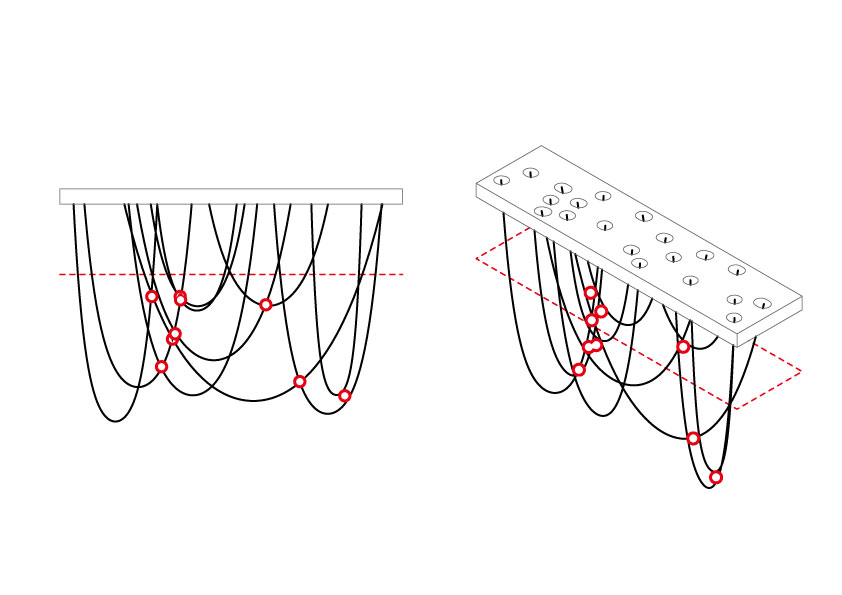

Intersection Height

Position of connections should be far away enough from the beam to ensure structural stability.

Structural Continuity

Each drilling point should have direct route for force transmission to the edge of the beam.

Human Evaluation / Decision

Searching for Optimized Placement Options

Human Evaluation / Decision

Real-time decisions controlling Design Outcome

Robotic Drilling and Assembly

Credits:

University of Tokyo Obuchi LaboratoryYusuke ObuchiShuta Takagi, Yusuke Komate

2021-2022Alex Orsholits, Zhou Li, Cheng Zhe Zhu, Kritika Dhupar

2020-2021Alex Orsholits, Annette Choi, Zhou Li

2019-2020Alex Orsholits, Aungsoe Pyaezone, Boon Hau Lim, Campbell Meredith Argenzio, Dominika Demlova, Hao Li, Ke Zhou, Surjyatapa Ray Choudhury, Yiyuan Qian, Yucheng Zeng, Annette Choi, Zhou Li

Digital Fabrication Research Collaborator:Shimizu Corporation Construction Technology Division

Construction:Shimizu Corporation

Mist Design:Panasonic Holdings CorporationManufacturing Innovation Division

Structural Design:University of Tokyo Jun Sato Laboratory

Pottery Production Advisor:LIXIL CorporationINAX Museums Cultural Promotion Department

Pottery Artist:Daisuke Tominoto, Sachiko Iketani