Books

Available for Purchase:

内容紹介

(currently only available in Japanese)

建築理論は、いま何を論じられるのか?

東京大学での議論から見えてくる建築の危機と継承される使命。

日本と西洋の“食違い”から未来が浮上する!

槇文彦、磯崎新、原広司ら、世界の第一線で活躍している建築家、建築評論家を一同に集め東京大学で行われた2つのシンポジウムを収録し、登壇者への個別インタビューとエッセイを加え、日本と海外における「建築理論」の現在について多角的に迫る一冊。

★T_ADSとは

東京大学建築学専攻Advanced Design Studiesの略称。最先端の建築デザイン教育と建築文化の向上に寄与することを目的として、隈研吾・千葉学・小渕祐介研究室が中心となり東京大学内に創設された組織。従来のように個々の研究室が独自の研究をおこなうだけでなく、グローバルとローカルが共存する社会で求められるテーマを分担した複数の「ラボ」が横断的に活動をおこなう。

【本書「FORWARD」(隈研吾)より】

1990年代以降、建築理論は世界的に停滞していて、静かであると言われる。建築家がグローバル経済の激流に翻弄され、考える時間、精神的余裕がなくなったからだとも言われる。しかし、9.11、3.11以降「考えざるを得ない状況」がわれわれの前に、すでにはっきりとした姿で現れている。その状況が、このシリーズをはじめるきっかけとなって、われわれは踏み出すことにした。

【主要目次】

Foreword(隈 研吾)

Preface(小渕祐介)

Symposium これからの建築理論(槇 文彦×磯崎 新×原 広司)

Essay 建築で何を学ぶのか(千葉 学)

Interview 都市と建築の思考とヒューマニズム(槇 文彦)

Essay 槇文彦の建築論――モダニズムの先(大野秀敏)

Interview 都市と建築をかき混ぜる物語(磯崎 新)

Essay 磯崎新から引き継いだこと、断ち切ろうとしたこと(青木 淳)

Interview 建築は、その気になれば先取りできるはずである(原 広司)

Essay 原広司から学びとったこと(小嶋一浩)

Symposium プロジェクション&レセプション(ジェフリー・キプニス×シルヴィア・レイヴィン×ジェシー・ライザー×梅本奈々子×ブレット・スティール)

Interview 建築文化を持続させるもの(ジェシー・ライザー+梅本奈々子)

Interview 建築が作動するところ(ジェフリー・キプニス)

Interview 建築のマルチ・プラットフォームは建築家に何を与えるのか(シルヴィア・レイヴィン)

Afterword(木内俊彦)

著者について

東京大学建築学専攻 Advanced Design Studies

最先端の建築デザイン教育と建築文化の向上に寄与することを目的として、隈研吾・千葉学・小渕祐介研究室が中心となり東京大学内に創設された組織。従来のように個々の研究室が独自の研究をおこなうだけでなく、グローバルとローカルが共存する社会で求められるテーマを分担した複数の「ラボ」が横断的に活動をおこなう。

Forthcoming (expected 2017):

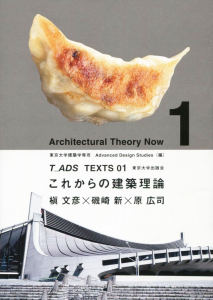

2013 Digital Fabrication Lab Pavilion: 99 Failures

2013 Digital Fabrication Lab Pavilion: 99 Failures

The first large-scale pavilion project produced by the Advanced Design Studies program through cooperation with a general contractor (Obayashi Corporation), this project would be the spark that would set off an agenda into explorations between how humans and machines can work together. The project focused on the use of robots to create custom components which were then inflated with water and arranged flat in a pre-determined pattern (connected with cords). The pattern was then hoisted with a crane and adjusted by humans on-site to create the complete tensegrity structure. The project highlighted the importance of human involvement on-site, and raised questions regarding how humans could be moved to the focus of the fabrication and construction processes.

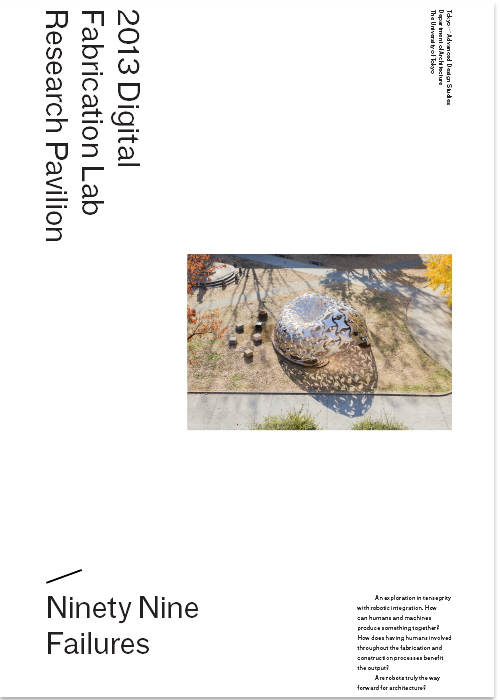

2014 Digital Fabrication Lab Pavilion: STIK

STIK (Smart Tool, Integrated Konstruction) put the questions raised by the 99 Failures project at the focus, asking how humans could be better integrated into the creation of architectural outputs. Marking a key leap in the agenda of the Advanced Design Studies program, this project was the first exploration into the use of a real-time scanning and guidance system. It was also an initial attempt to transform a material understood as waste into a construction material. Through scans of the work in progress and comparison to a pre-determined target model, a responsive color map was displayed for workers to follow. Utilized both on-site (under cover of darkness) and in a dimmed laboratory environment (for panelized fabrication), the system indicated great adaptability and a capacity to integrate error. The key question raised with the STIK pavilion was how errors could be better integrated into the fabrication process, and whether the errors could inform updates to the pre-determined geometry.

2015 Digital Fabrication Lab Pavilion: TOCA

2015 Digital Fabrication Lab Pavilion: TOCA

In a continuation of the themes initially explored in the STIK project, the TOCA (Tool Operated Choreographed Architecture) pavilion project placed humans at the focus of the fabrication and construction process, and also used a scanning system to compare actual outputs to pre-determined geometries. Similar to STIK, TOCA utilized a non-traditional material to create components: fast-drying spray foam. To create the pavilion, a pre-determined lattice pattern was first defined. Next, teams of workers sprayed crossing arcs of the spray foam, beginning and ending at pre-determined points. They sprayed the arcs in a ring, and when all arcs in a ring were completed, each of the key points (marked with an AR code) was scanned and compared to the original target geometry. The system recognized the errors and created an updated geometry for the next stage of construction. This scanning and optimization-based approach was capable of integrating even significant errors. Over the course of the project, it became apparent that some workers were more adept at the component fabrication process than others, and thus a small team of individuals became “experts” for the project. This raised a question for further exploration: how might workers with different skill levels be utilized to produce an adaptive architectural output?

2016 Digital Fabrication Lab Pavilion: Computational Clay

2016 Digital Fabrication Lab Pavilion: Computational Clay

In 2016, in an effort to explore how workers with different levels of skill might be able to participate equally in the fabrication and construction processes, the Computational Clay pavilion project utilized a panelized approach to construction. Panels were produced by pairs of workers under a scanning and guidance system. Workers pushed and held panels in locations designated by the guidance, which compared the panel output in real-time to a pre-defined panel. In this way, workers with different physical capabilities could participate in the fabrication process. Arches in the pavilion were created panel by panel and were assembled on-site, where they were scanned as as global structure and compared to a pre-determined global structure. The results of the scan were analyzed and an optimized series of panels for subsequent fabrication was provided to workers. The final output proved to be quite time-consuming to produce, and although a recycled material (wood debris from demolition sites) was successfully utilized, the output did not heavily feature a unique human capability as the driver for fabrication. This is a key question for future studies.