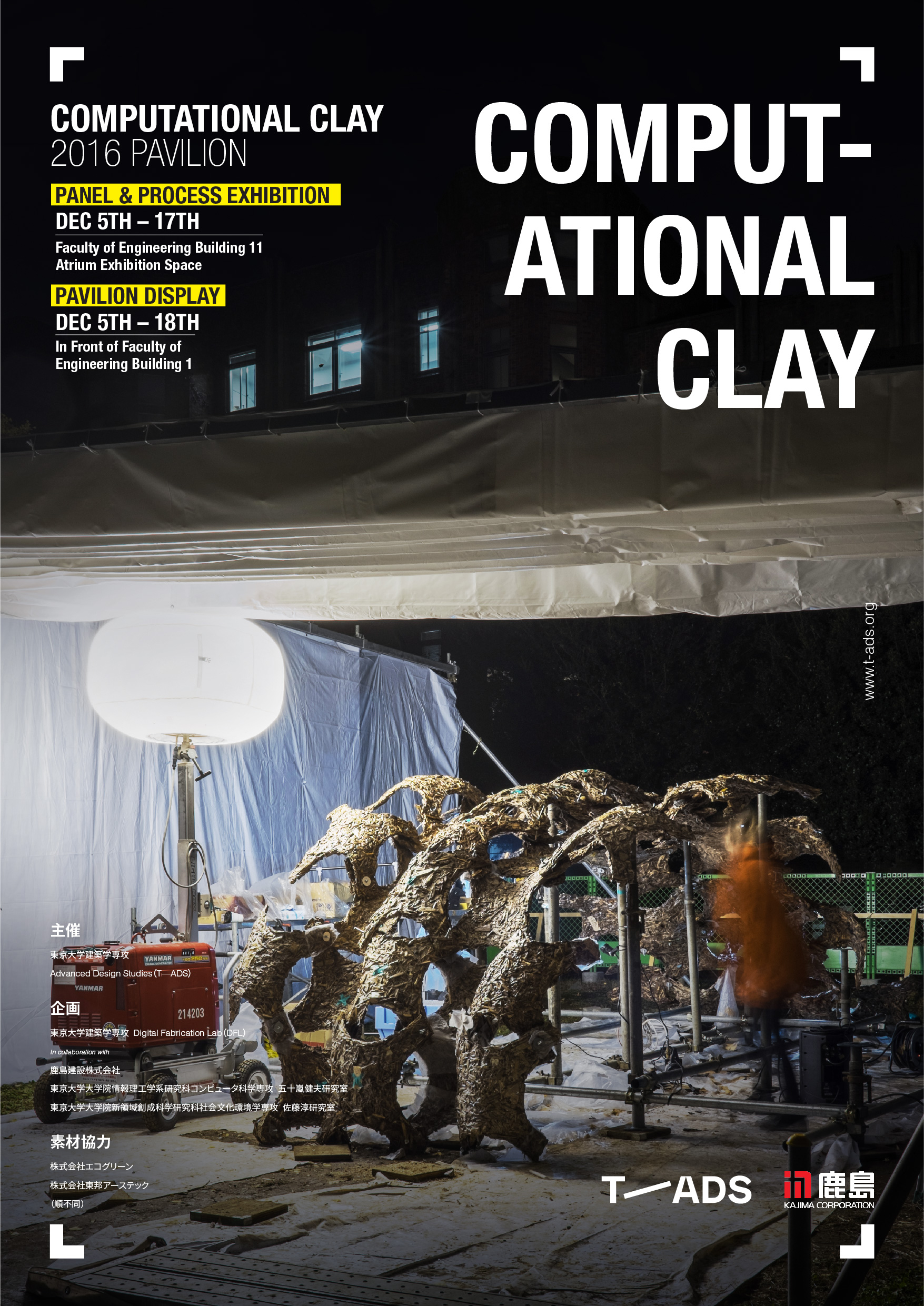

パビリオン公開 // PAVILION DISPLAY

12月5日(月)– 12月18日(日)// December 5 (Mon) – December 18 (Sun)

10:00 – 17:00

東京大学本郷キャンパス工学部1号館前広場

The University of Tokyo, Hongo Campus, Engineering Building #1 Plaza

パネル・模型展示 // PANEL AND PROCESS EXHIBITION

12月5日(月)– 12月17日(土)// December 5 (Mon) – December 17 (Sat)

平日と土曜日のみ // Weekdays and Saturdays only

(12月5日は13:00から) // (Open at 13:00 on December 5)

東京大学本郷キャンパス工学部 11 号館1階展示スペース(入場無料)

The University of Tokyo Hongo Campus, Engineering Building #11, 1F Exhibition Space (free entry)

主催: 東京大学建築学専攻 Advanced Design Studies(T—ADS)

PRODUCED BY: Advanced Design Studies, Department of Architecture, The University of Tokyo

企画: 東京大学建築学専攻 Digital Fabrication Lab(DFL)

鹿島建設株式会社

東京大学大学院情報理工学系研究科コンピュータ科学専攻 五十嵐健夫研究室

東京大学大学院新領域創成科学研究科社会文化環境学専攻 佐藤淳研究室

素材協力: 株式会社エコグリーン、株式会社東邦アーステック(順不同)

PLANNING:

Digital Fabrication Lab (DFL), Department of Architecture, The University of Tokyo

IN COLLABORATION WITH:

Kajima Corporation

Graduate School of Information Science and Technology, Department of Computer Science, Takeo Igarashi Laboratory

Graduate School of Frontier Sciences, Department Socio-cultural Environmental Studies, Jun Sato Laboratory

MATERIALS PROVIDED BY:

Eco Green, Toho EarthTech (in random order)

東京大学建築学専攻Digital Fabrication Lab(DFL)では、建築施工におけるデジタル技術の活用をテーマに、毎年実験的なパビリオンを制作しています。単に技術による自動化や高度化を目指すのではなく、そこに「人間が関わること」の可能性を探る実証の場として、これまで「人間と機械が融合した3Dプリンター」(2014年STIKパビリオン)や「巨大3Dペン」(2015年TOCAパビリオン)を建築スケールで再現してきました。

本年Computational Clayプロジェクトでは「人間が関わること」をより一層推し進め、個性としての身体パフォーマンスを建築表現に反映させるため、人の動きと素材と関係に着目したユニークなパネル加工システムを開発しました。

Every year in the University of Tokyo’s Digital Fabrication Lab (DFL), digital fabrication technologies are used to produce an experimental pavilion project. The aim, rather than being simply to achieve automation or precision through use of such technologies, is to explore the potentials for human and machine collaboration. Past projects have focused on fusions between humans and machines through the use of 3D printers: the 2014 STIK Pavilion explored this theme through guided aggregation, and the 2015 TOCA Pavilion by using humans as a parameter along with an oversized 3D pen.

This year, in the Computational Clay Pavilion, we advance the role of the human in construction one step further, examining how an individual’s capabilities and performance can be expressed in an architectural output. We have developed a unique panelized construction system wherein the movements of humans and their relationship to the material are explored.

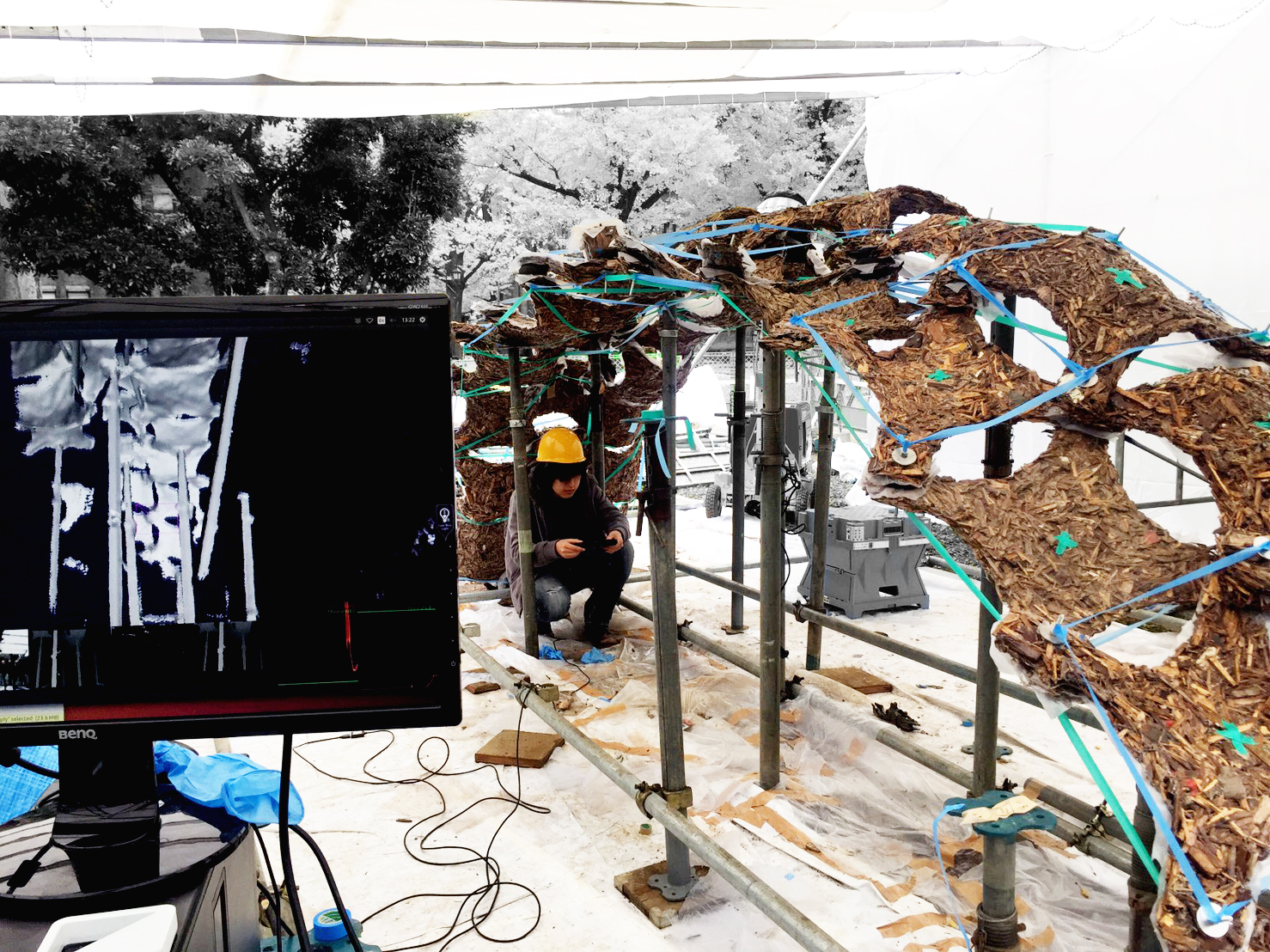

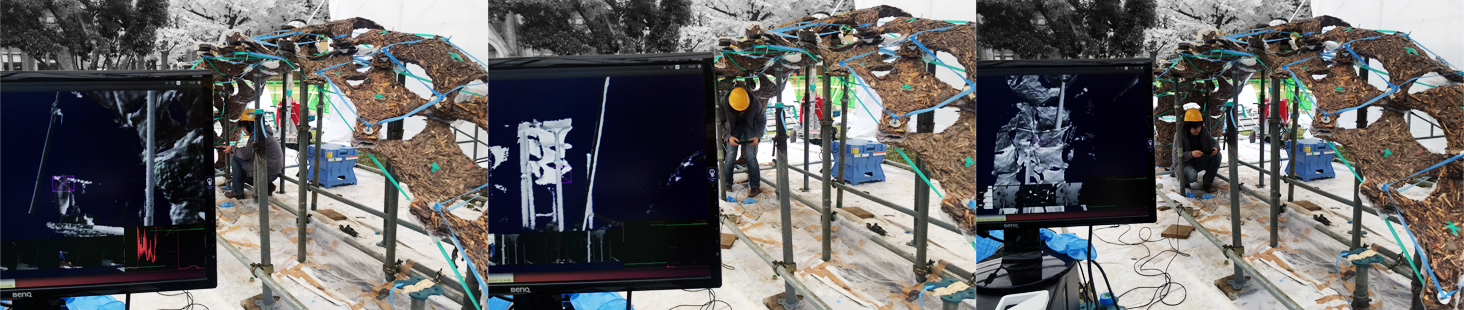

Two arches completed on-site.

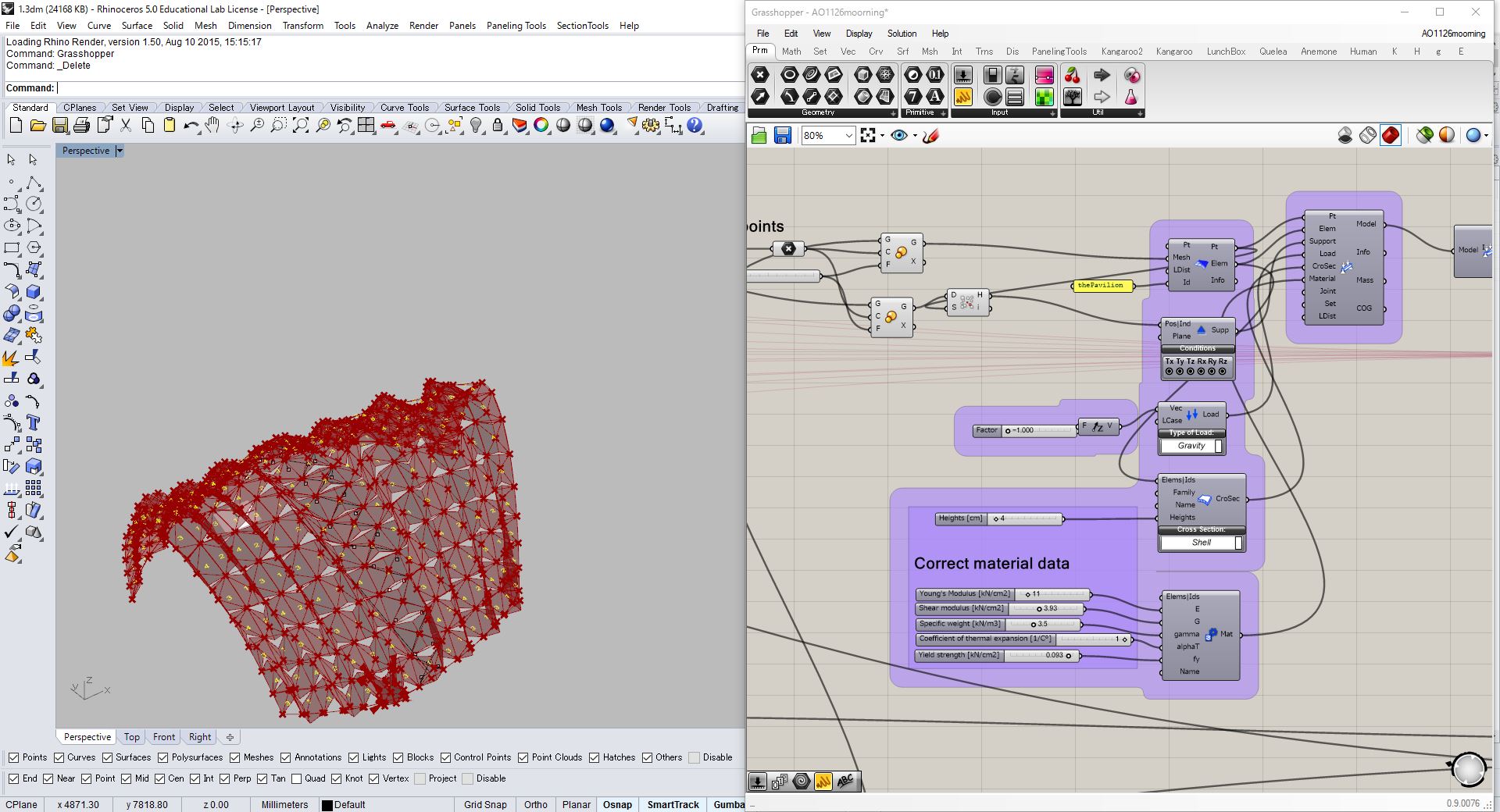

Structural optimization.

Guidance sequence.

Scanning process on-site.

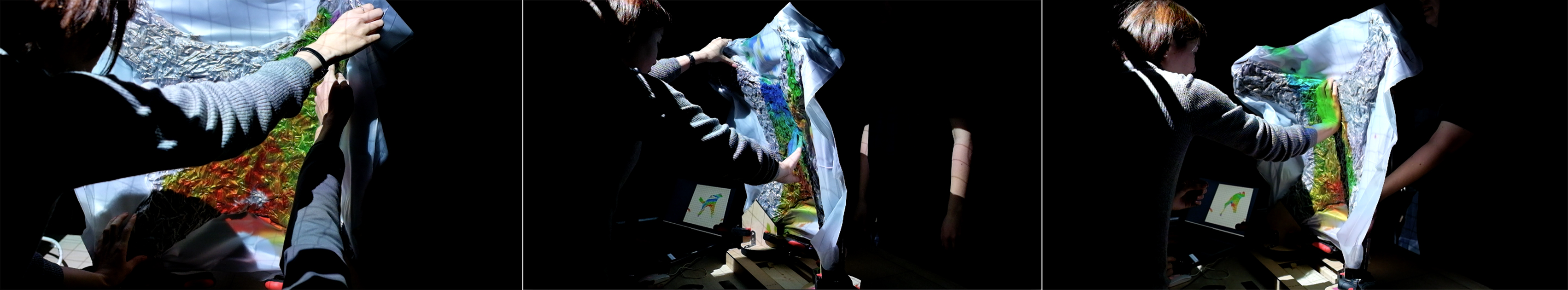

Panel-making process.

Preparation for guidance.

Scanning sequence.

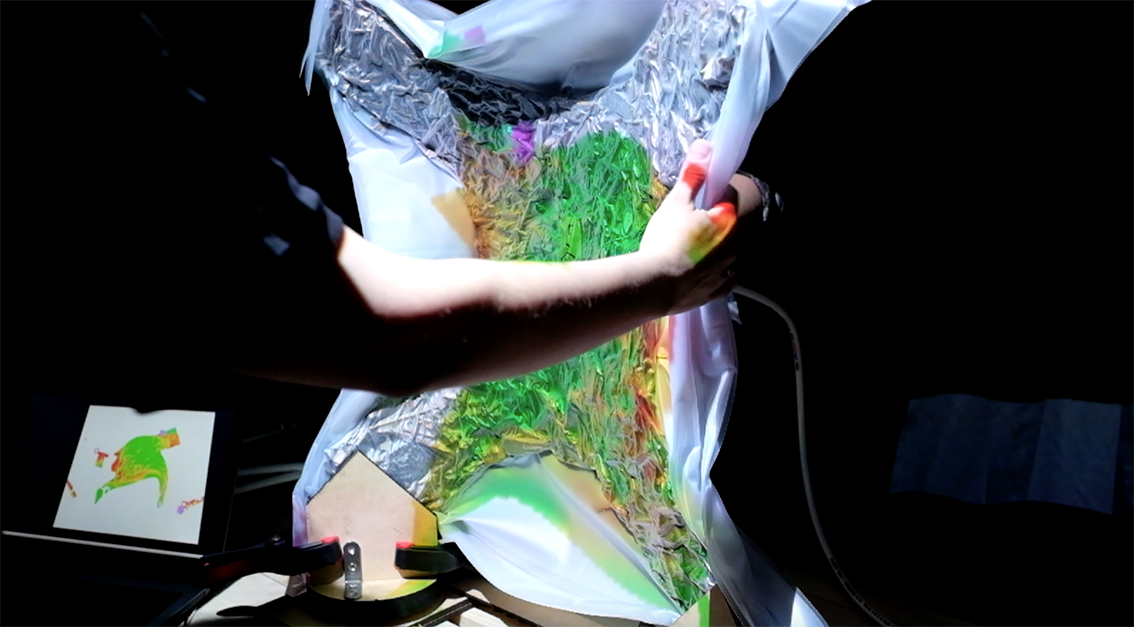

The two images show the stages of panel production used for the 2016 pavilion project.

Panel Bag Sealing Steps (image 1):

Step 1: Wood chips are mixed with resin and poured into a pre-made wooden frame, which sits on top of a double layer of plastic bags to decrease possibility of holes forming.

Step 2: The frame is removed and another double layer of plastic is put on top of the wood chips. The outer bag is then closed with a heat sealer. Two adjacent lines of sealant help to prevent air leakage during vacuuming.

Step 3: The panel is vacuumed and any small holes that may be produced due to the combination of sharp wood chips and high pressure are taped.

Step 4: Reflective marker guidance system tracking points are applied. This is for the panel shaping process, which comes next.

Panel Shaping Process (image 2):

A Kinect camera uses an infrared projector to detect the contrast between reflective markers and the background. When it finds a point of contrast it produces a tackable point, which is then compared to predetermined points in the computer model. The manipulation of the panel is articulated according to the difference between the points on the model and the points (reflective markers) on the actual panel. After the panel has been shaped, the points are re-scanned to quantify the difference between the physical and computer models. A light-absorbing cloth is used as a backdrop to create total contrast between the panel and its environment. This allows the physical panel to be easily tracked and manipulated in space.

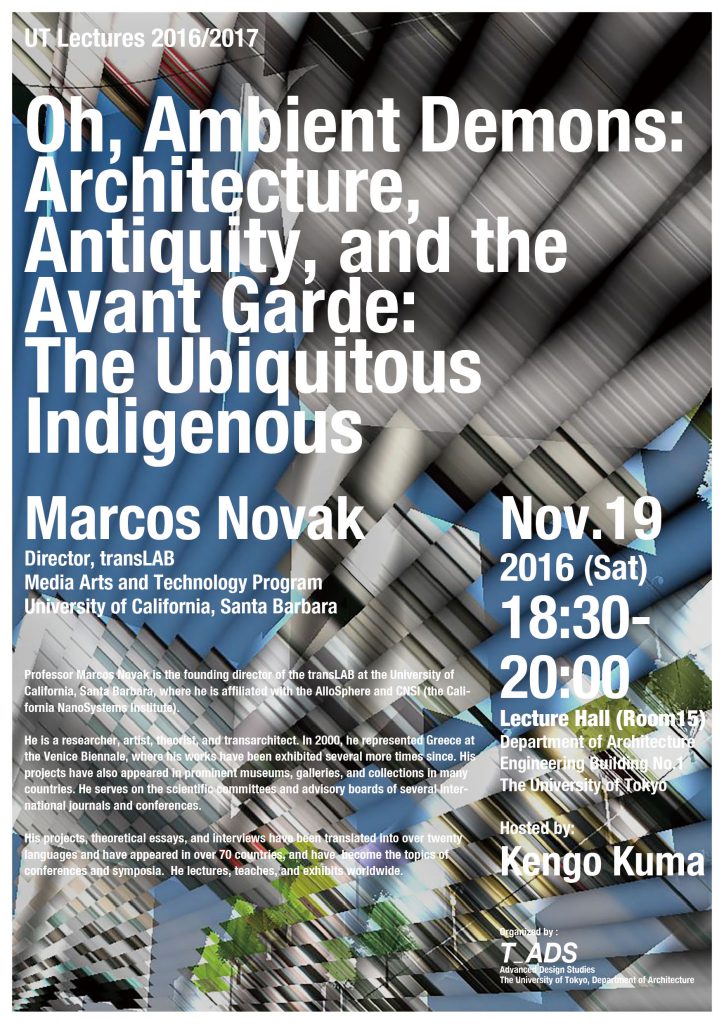

Please join us on Saturday, November 19 in Lecture Hall 15 of Engineering Building #1 for a lecture from Marcos Novak. Novak is the Director of transLAB in the Media Arts and Technology Program at the University of California, Santa Barbara.

Professor Marcos Novak is the founding director of the transLAB at the University of California, Santa Barbara, where he is affiliated with the AlloSphere and CNSI (the California NanoSystems Institute).

He is a researcher, artist, theorist, and transarchitect. In 2000, he represented Greece at the Venice Biennale, where his works have been exhibited several more times since. His projects have also appeared in prominent museums, galleries, and collections in many countries. He serves on the scientific committees and advisory boards of several international journals and conferences.

His projects, theoretical essays, and interviews have been translated into over twenty languages, have appeared in over 70 countries, and have, and have become the topics of conferences and symposia. He lectures, teachers, and exhibits worldwide.

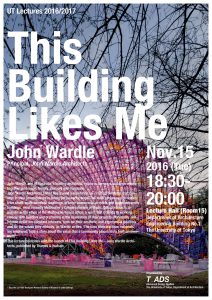

Please join us at 18:30 on November 15, 2016 in room #15 of Engineering Building #1 for a lecture from Australian architect John Wardle.

Lecturer: John Wardle (Principal, John Wardle Architects)

Lecture Title: This Building Likes Me

Date: November 15, 2016

Time: 18:30-20:00

Location: Lecture Hall #15 (Room 15), Engineering Building #1, the University of Tokyo

Lecture Description: John Wardle, one of Australia’s leading architects, explores the ways buildings weave together landscape, history, memory, and materials.

John Wardle Architects (JWA) has gained a reputation for creating buildings that connect to their surroundings in subtle yet powerful ways. The work ranges across scales: from small-scale domestic dwellings, to large commercial projects and major university buildings, most recently, Melbourne’s Conservatorium of Music. Collaboration is ingrained in the those of the Melbourne-based office, a spirit that extends to working closely with builders and craftsmen in the realization of their projects. Materiality and intense detail are constant interests, both for their aesthetic and experiential qualities and for the values they embody, as Wardle writes: “The care shown in how materials are employed, tells a story about the value that a community places in its built environment.”

This lecture coincides with the launch of This Building Likes Me – John Wardle Architects, published by Thames & Hudson

The below information is for reference purposes only.

Admission Information: http://www.global30.t.u-tokyo.ac.jp/g30_hp/architecture-and-urban-design.html#guidance

Start your application here: https://t-cens.iapply.t.u-tokyo.ac.jp/t-cens/login_screening.php

Application Guide: https://t-cens.iapply.t.u-tokyo.ac.jp/guidance_information/

ONLINE APPLICATION

POSTAL APPLICATION

FINAL RESULT NOTIFICATION

Find further information about the course and the University of Tokyo:

EXHIBITION: The Scene of New Architectural Educationー新しい建築教育の現場

Obuchi lab is featured at this exhibition hosted by the LIXIL Ginza Gallery.

June 12, 2016 (Sunday) – August 22, 2016 (Monday)

Closed: Wednesdays, August 10-17

Open Hours: 10:00-18:00

Admission: Free

Cooperation: Kengo Kuma and Associates, LIXIL GALLERY

Staff and students visited several islands in Japan’s Inland Sea last week in an effort to see and experience international and domestic art and design. The itinerary for the trip included Shodoshima, Inujima, Teshima, and Naoshima.