Kizuki-au、築き合う– Collaborative Constructions

Our globalised societies have entered a new phase. The pandemic has revealed how our communities are intricately linked beyond borders and how mutually dependent we are in an evermore fragile world. Meanwhile, the popularization of online communication demonstrates how technology helps us re-connect even in forced isolation; we could talk to anyone, anywhere, anytime. In this emerging order, how can architecture reimagine its tradition and role in society?

Collaborative Constructions investigates a new practice of architecture based on the creative, innovative and personal use of technology. The projects by Gramazio Kohler Research at ETH Zurich, and T_ADS Obuchi Lab of the University of Tokyo engage in a collaboration seeking architectural strategies to relate nature and humanity through technology; human-robot collaborations exemplify how we can engage with the past while looking ahead.

The project reimagines Tokoname with its post-industrial legacy, through an extended notion of empathy: its people, traditions, history, environment and culture are intertwined and made tangible through digital fabrication. Architecture becomes an expression of being alive.

The project is an initiative of the Embassy of Switzerland in Japan, ETH Zurich and the University of Tokyo, in collaboration with Shimizu Corp. It is part of the Vitality.Swiss program.

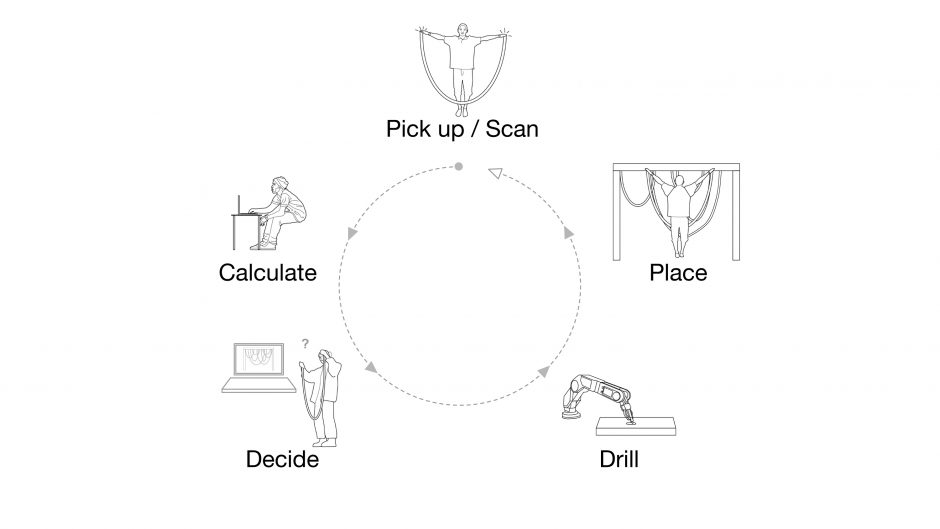

Participatory Shape Generation

Each person makes a uniquely defined shape of pottery chain by holding it with different physiques and strengths reflecting their individuality.

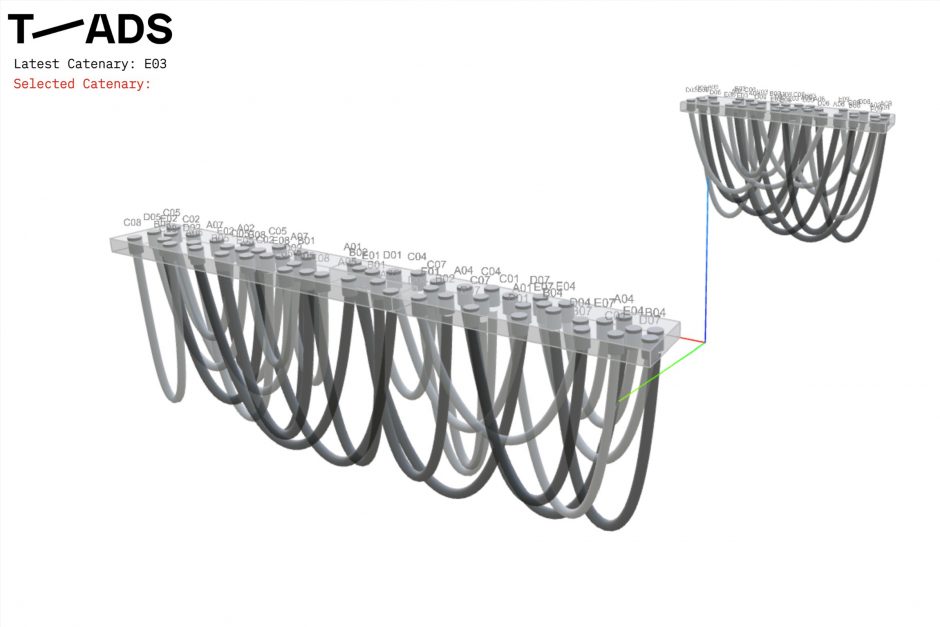

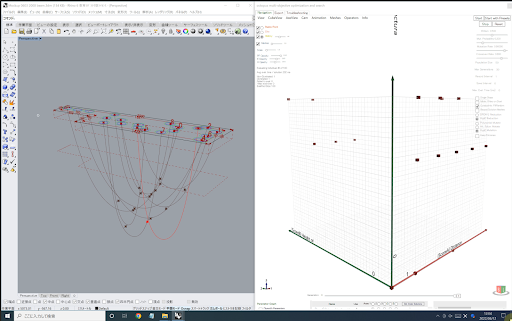

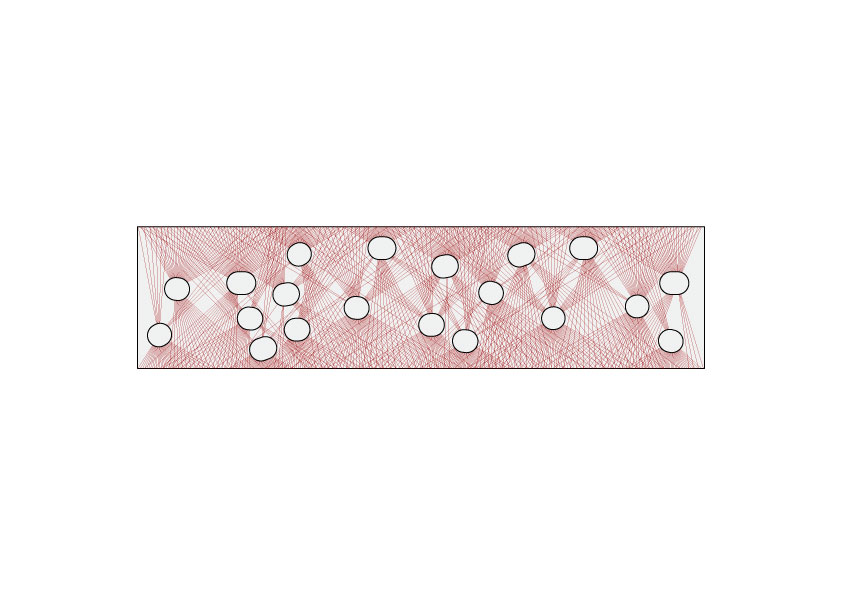

Real-time Optimization

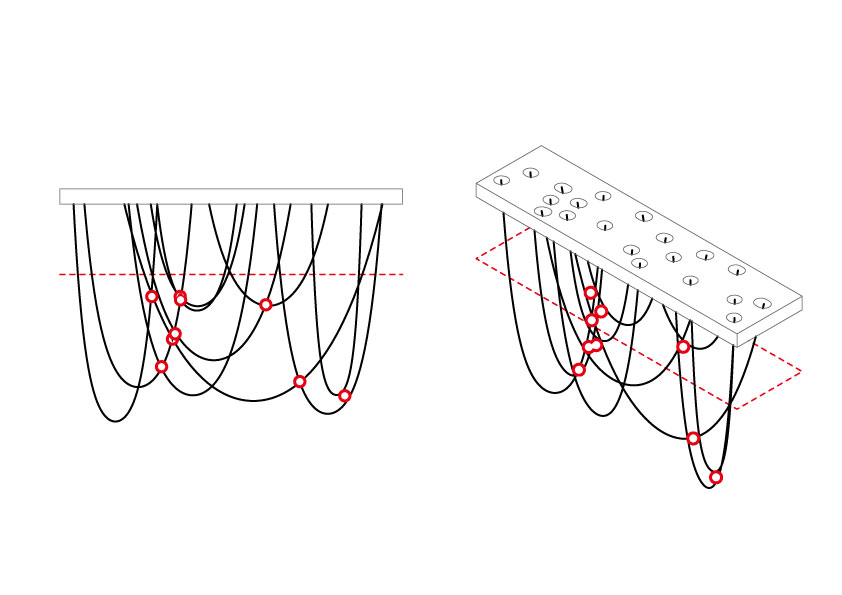

The heart of the project is the fabrication of the hanging pottery chains. While the pattern appears to be random at first glance, its generation requires an intricate algorithm, an algorithm that brings humans and machines together.

Robotic Drilling

“Collaborative Constructions” combines elements of traditional architectural construction, culture, and natural materials with modern digital technologies such as computational design and robotics fabrication.

Collaborative Constructions

Process Chronology

Human Scaled Participatory Shape Generation

The pottery chains are created by a series of feedback processes between a person and a robot. The pottery chains are created by a series of feedback processes between a person and a robot. Sensors are placed on each subject’s hand so that the information-gathering process is as natural as possible.

Real-time Optimization Controlling Design Outcome

Optimization Criteria

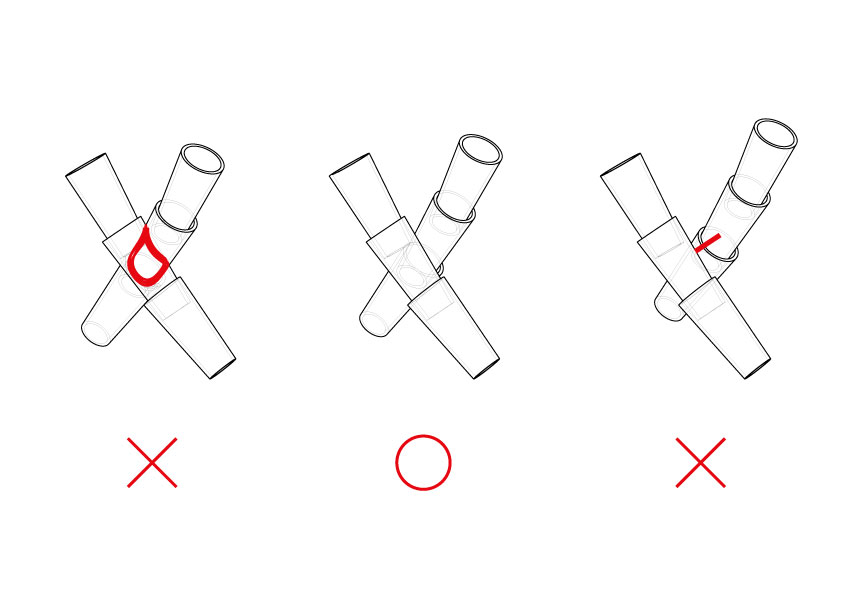

Tangential Connections

Distance between catenaries should be within a certain domain to avoid intersection, but meanwhile should allow to be tied together.

Intersection Height

Position of connections should be far away enough from the beam to ensure structural stability.

Structural Continuity

Each drilling point should have direct route for force transmission to the edge of the beam.

Human Evaluation / Decision

Searching for Optimized Placement Options

Human Evaluation / Decision

Real-time decisions controlling Design Outcome

Robotic Drilling and Assembly

Credits:

University of Tokyo Obuchi LaboratoryYusuke ObuchiShuta Takagi, Yusuke Komate

2021-2022Alex Orsholits, Zhou Li, Cheng Zhe Zhu, Kritika Dhupar

2020-2021Alex Orsholits, Annette Choi, Zhou Li

2019-2020Alex Orsholits, Aungsoe Pyaezone, Boon Hau Lim, Campbell Meredith Argenzio, Dominika Demlova, Hao Li, Ke Zhou, Surjyatapa Ray Choudhury, Yiyuan Qian, Yucheng Zeng, Annette Choi, Zhou Li

Digital Fabrication Research Collaborator:Shimizu Corporation Construction Technology Division

Construction:Shimizu Corporation

Mist Design:Panasonic Holdings CorporationManufacturing Innovation Division

Structural Design:University of Tokyo Jun Sato Laboratory

Pottery Production Advisor:LIXIL CorporationINAX Museums Cultural Promotion Department

Pottery Artist:Daisuke Tominoto, Sachiko Iketani

東京大学 小渕祐介研究室、佐藤淳研究室がプロジェクトサポートとして参画した「ヴェネチア・ビエンナーレ国際建築展 アラブ首長国連邦(UAE)館: Wetland」が最優秀賞にあたる金獅子賞を授賞しました。

小渕研究室は佐藤研究室と協働し、プロジェクトの初期段階から現地における施工段階まで、デジタルファブリケーションシステムの開発を担当しました。

施工計画をはじめとし、デジタル計測/施工ツールデザインや、施工の観点からのマテリアルデザインを通じて、これまでの小渕研究室のテーマでもあった「リアルタイム/オンラインでの施工プロセスの最適化」を追求し、世界規模の感染症が蔓延する状況の中、国際的なリモート環境でデジタルファブリケーションシステムを実現しました。

Venice Biennale Architecture Exhibition is one of the most respected architecture exhibitions in the world. With a request from Kenichi Teramoto and Wael Al Awar, curators of the UAE (United Arab Emirates) National Pavilion, Jun Sato’s laboratory and Yusuke Obuchi’s laboratory collaborated to support the UAE’s commissioners and ambitions. The UAE produces a large amount of salt as a byproduct during the desalination process of seawater. The main concept of the pavilion was to utilize magnesium, which was extracted from the salt, and use it as a hardening agent for building parts made of cement.

Sato-Lab proposed a simple solution for the production of 2500 pieces of the cement parts within a tight time constraint; make shallow trenches in the ground as a formwork and pour cement to be cured. This production process resulted in the making of “coral-shaped” pieces. We also proposed a structural design by synchronizing with Obuchi sensei’s digital fabrication guiding system for sequential structural optimization to develop an assembly logic.

Obuchi-Lab has designed and developed a human centric digital fabrication system which supported assembly crew members on site by connecting them with real-time spatial and geometrical information of the 2500 pieces to be installed in a designated area. When pieces were installed in a shape of ring and formed a layer, collected spatial data of installed pieces was then analyzed for structural stability and overall geometrical accuracy. In the end of the fabrication process, we were able to create an architectural form as a result of integrating technology and nature, and craftsmanship and machine.

It is a great honor to be part of the work that received the Golden Lion, the highest award given , at this prestigious exhibition.

Joint statement by Jun Sato and Yusuke Obuchi

第17回 ヴェネチア・ビエンナーレ 国際建築展 審査委員長である妹島和世氏から、以下のようなメッセージを頂きました。

| 今回のベネチアビエナーレは、これまで以上に建築の枠を超えた新しい可能性を感じられる展示作品がたくさんありました。特に多くの最先端のテクノロジーを応用した作品には驚きました。また、ナショナル・インターナショナル、どちらのパビリオンにおいても、国境を超えてさまざまな国々から集まって構成され、そして企画された展示が多くみられ、UAEパビリオンも中東、日本、アメリカなど複数の国々からのメンバーで成り立っており、そこで東京大学の2つの研究室が技術協力を行なった事はとても嬉しく思いました。日本においてもこれ迄以上に研究活動が海外に広がり活躍されることを期待しています。小渕先生と佐藤先生、素晴らしい作品、金獅子賞おめでとうございます。

妹島和世 |

| At this Venice Biennale, there were many exhibited works that dealt issues beyond the convention of architecture more than ever and hinted new possibilities. I was particularly surprised to see many works that applied cutting-edge technologies. Also, in both National and International pavilions, there were many exhibitions organized by a team of participants joined from various countries across national borders. The UAE Pavilion’s team was also made up of collaborators from multiple countries such as the Middle East, Japan, and the United States. I was very pleased that the two laboratories of the University of Tokyo provided technical corporation for the work. I hope that research activities in Japan will expand more and reach out overseas and play an active role.

Congratulations to Dr. Obuchi and Dr. Sato for their wonderful work and the Golden Lion Award. Kazuyo Sejima, Architect |

DataSheet

- プロジェクト期間:2019年12月 – 2021年8月

- 担当業務:

- 小渕祐介研究室

- パビリオンのデジタルファブリケーションシステムデザイン

- コンクリート部材位置のスキャニングツール、システムの開発

- コンクリート部材施工のガイディングツール、システムの開発

- コンクリート部材配置のオンラインデータベースの構築

- 構造最適化計算のオンライン統合ネットワークシステムの構築

- webサイト開発(https://venice2021.t-ads.org/) 開発:Alex Orsholits

- 佐藤淳研究室

- 構造設計

- コンクリート調合設計

- ピース形状スタディ、最適化

- モックアップ構造実験

- 構造最適化プログラム開発

- 2研究室協働

- 立体形状最適化、決定

- 平面計画、立面計画

- ドキュメント作成、記録

- 小渕祐介研究室

The University of Tokyo project team

Yusuke Obuchi,Associate Professor, Department of Architecture

Jun Sato, Associate Professor, Department of Socio Cultural Environmental Studies

Shuta Takagi, Obuchi Lab Support Specialist

Yusuke Komata, Obuchi Lab Support Specialist

Project consultants (Sato Lab)

Mika Araki, Associate Professor, Kwansei Gakuin University School of Architecture / Mika Araki Structural Engineers

Kosuke Suehiro, Jun Sato Structural Engineers Co., Ltd.

Obuchi Lab – student assistant credit list

Construction System & Network Development: Alex Orsholits

Scanning & Guiding Hardware Design: Zhou Li

System Documentation: Annette Choy de Leon

Scanning System: Pyaezone Aungsoe, Meredith Campbell Argenzio, Boon Hau Lim, Surjyatapa Raychoudhury

Guidance System: Yiyuan Qian

Sato Lab – student assistant credit list

Structural Optimization System Development: Ren Imai, Shimpei Kojima, Yusuke Shimoyamada

Manufacturing & Structural Assemblage Development: Hirotaka Ujioka, Kenta Isebo

Construction Test: Ryoma Kanazawa, Miho Wada, Kousuke Miyano

Official Credit

Commissioner: Salama Bint Hamdan Al Nahyan Foundation

Supporter: UAE Ministry of Culture and Youth

Curators: Wael Al Awar and Kenichi Teramoto

Venue: Arsenale

Exhibitors

Urban Researchers: Ahmed & Rashid Bin Shabib

Researchers

Wetland Research Team

New York University, Abu Dhabi, Amber Lab

University of Tokyo, Sato Lab and Obuchi Lab

American University of Sharjah, Department of Biology, Chemistry and Environmental Sciences

https://www.labiennale.org/en/news/awards-17th-international-architecture-exhibition

Release

Venice Biennale AWARDS Official Release:

https://www.labiennale.org/en/news/awards-17th-international-architecture-exhibition

designboom:

https://www.designboom.com/architecture/uae-golden-lion-best-national-pavilion-venice-architecture-biennale-08-30-2021/

ArchDaily:

https://www.archdaily.com/967667/uae-wetland-wins-the-golden-lion-for-best-national-participation-at-the-2021-venice-biennale

Can the integration of digital technologies in design and construction processes be used for expressing personal tendencies through the creation of new architectural practices as well as novel aesthetics?

The University of Tokyo Digital Fabrication Lab (DFL) has annually been involved in an experimental pavilion installation, aiming at the application of digital technologies to architectural construction. Its projects are the embodiments of human-machine interaction, demonstrating its unique fabrication systems that make a worker behave as part of a 3D printer; translating human movement into formwork.

At the DFL, we believe that the role played by digital technologies in design and construction does not necessarily have to make them more efficient and streamlined. Their potential is instead focused on personalising the fabrication process. In our view, the act of making as such becomes a design in itself by means of computer assistance. The diversity that humans collectively show is organically expressed in the architecture.

PAFF is an architecture made by reference to sound rather than visual information. We developed a sound guidance system whereby a worker’s task is to recognise a sound source in a three-dimensional space, and shoot fibres into various targets. PAFF is expressed through the accumulation of the multi-agent system, revealing personal differences in the way that people perceive space through sound.

Project Credits:

UNIVERSITY OF TOKYO ADVANCED DESIGN STUDIES PROFESSORS

Yusuke Obuchi

Jun Sato

UNIVERSITY OF TOKYO PROJECT MANAGEMENT

Shohei Furuichi

Shuntaro Nozawa

Shuta Takagi

Deborah Lopez Lobato

Hadin Charbel

PROJECT COLLABORATOR

TAISEI CORPORATION

SPONSOR

TAISEI CORPORATION

SECOND YEAR STUDENT TEAM

Mika Kaibara Portugaise

Ziyi Wu

Nathalia Barros Abate Rotelli

Ruta Stankeviciute

Xiaoke Chen

Ao Yang

FIRST YEAR STUDENT TEAM

Ruoyu Chen

Wanting Liu

Yuqing Shi

Anran Wang

Yuxi Zhu

Sher Lin Tan

Otto Lindstam

Sofia Iino Cotado

Dominika Demlova

Priya Murugeswaran

ADDITIONAL SUPPORT

Machiko Asahara

Kyosuke Kawamura

Kota Isobe

PHOTOGRAPHS

Otto Lindstam

Yuqing Shi

DFL Research Pavilion 2017

PAFF (Projectile Acoustic Fibre Forest)

パビリオン展示

2017/11/28 – 2017/12/10, 10:00-17:00

In Front of Faculty of Engineering Building 1, Hongo Campus

東京大学本郷キャンパス工学部1号館前広場

パネル・模型展示

2017/11/28 – 2017/12/09, 7:00-18:00 (Weekdays and Saturday)

T lounge, Faculty of Engineering Building 11

東京大学本郷キャンパス工学部11号館1階T lounge

*12/02はシンポジウム開催に合わせ、15:00から16:00までの間、プロジェクト関係者がパビリオン及びエキシビション会場に常駐しております。どうぞお気軽にお声がけ下さい。

シンポジウム

Human Centric Digital Fabrication 人間主体のデジタル・ファブリケーション

2017/12/02, 16:00-19:00 (開場15:30)

東京大学工学部1号館15号講義室 (定員100名先着順 入場無料)

デジタル技術が可能にするデザインと施工プロセスの一体化は、つくることを通じた個の表現を促し、建築を変えることができるか?

東京大学建築学専攻Digital Fabrication Lab(DFL)では、建築施工におけるデジタル技術の活用をテーマに、毎年実験的なパビリオンを制作しています。これまで、人間がコンピュータのナビゲーションに従って施工する人機一体3Dプリンターや人間の動きそのものを型枠に見立てたファブリケーション・システムを建築スケールで再現してきました。

DFLがデジタル技術に求めているのは、デザインや施工を効率的にする役割のみに限りません。DFLが着目しているのは、デジタル技術の媒介によってつくるという行為自体がデザイン・プロセスとなり、人間が総体として持つばらつきが建築として有機的に表現される可能性です。

本年プロジェクトPAFFは、目ではなく耳を頼りにしてつくる建築です。作業者が音のガイドを聞きながら空間的広がりや奥行きを感知し、ターゲットに繊維素材を吹き飛ばす施工システムに挑戦します。音の世界を三次元的に認識しようとする過程で表出する個人差に着目し、それが重なり合ってできる建築を目指します。

シンポジウムでは、人間の個性や多様性、人間がつくることの不確実性を楽しむプロセスとしての施工について考えます。本年プロジェクトの共同実施企業である大成建設のプロジェクト・メンバーや建築とは異なる分野でご活躍される方々をお招きし、人間がつくることとデジタル技術の関係について議論します。

第1部(16:00-)

小渕 祐介 東京大学大学院工学系研究科建築学専攻 准教授

中野 優 大成建設株式会社建築本部 技術部長

佐藤 淳 佐藤淳構造設計事務所 主宰

東京大学大学院新領域創成科学研究科社会文化環境学専攻 准教授

第2部(17:30-)

権藤 智之 東京大学建築生産マネジメント寄付講座 特任准教授

稲見 昌彦 東京大学先端科学技術研究センター 教授

JST ERATO 稲見自在化身体プロジェクト 研究総括

新木 仁士 ARスポーツ「HADO」開発者、株式会社meleap CAO

総括

隈 研吾 建築家、東京大学大学院工学系研究科建築学専攻 教授

主催

東京大学建築学専攻Advanced Design Studies (T_ADS)

企画

東京大学建築学専攻Digital Fabrication Lab (DFL)・小渕祐介研究室

共同実施

大成建設株式会社

東京大学大学院新領域創成科学研究科社会文化環境学専攻佐藤淳研究室

(順不同)

東京大学建築学専攻Digital Fabrication Lab(DFL)では、建築施工におけるデジタル技術の活用をテーマに、毎年実験的なパビリオンを制作しています。単に技術による自動化や高度化を目指すのではなく、そこに「人間が関わること」の可能性を探る実証の場として、これまで「人間と機械が融合した3Dプリンター」(2014年STIKパビリオン)や「巨大3Dペン」(2015年TOCAパビリオン)を建築スケールで再現してきました。

本年Computational Clayプロジェクトでは「人間が関わること」をより一層推し進め、個性としての身体パフォーマンスを建築表現に反映させるため、人の動きと素材と関係に着目したユニークなパネル加工システムを開発しました。

Every year in the University of Tokyo’s Digital Fabrication Lab (DFL), digital fabrication technologies are used to produce an experimental pavilion project. The aim, rather than being simply to achieve automation or precision through use of such technologies, is to explore the potentials for human and machine collaboration. Past projects have focused on fusions between humans and machines through the use of 3D printers: the 2014 STIK Pavilion explored this theme through guided aggregation, and the 2015 TOCA Pavilion by using humans as a parameter along with an oversized 3D pen.

This year, in the Computational Clay Pavilion, we advance the role of the human in construction one step further, examining how an individual’s capabilities and performance can be expressed in an architectural output. We have developed a unique panelized construction system wherein the movements of humans and their relationship to the material are explored.

Project Credits:

主催: 東京大学建築学専攻 Advanced Design Studies(T—ADS)

PRODUCED BY: Advanced Design Studies, Department of Architecture, The University of Tokyo

企画: 東京大学建築学専攻 Digital Fabrication Lab(DFL)

鹿島建設株式会社

東京大学大学院情報理工学系研究科コンピュータ科学専攻 五十嵐健夫研究室

東京大学大学院新領域創成科学研究科社会文化環境学専攻 佐藤淳研究室

素材協力: 株式会社エコグリーン、株式会社東邦アーステック(順不同)

PLANNING:

Digital Fabrication Lab (DFL), Department of Architecture, The University of Tokyo

IN COLLABORATION WITH:

Kajima Corporation

Graduate School of Information Science and Technology, Department of Computer Science, Takeo Igarashi Laboratory

Graduate School of Frontier Sciences, Department Socio-cultural Environmental Studies, Jun Sato Laboratory

MATERIALS PROVIDED BY:

Eco Green, Toho EarthTech (in random order)

UNIVERSITY OF TOKYO DIRECTING PROFESSORS

Yusuke Obuchi (Associate Professor), Department of Architecture

Jun Sato (Professor), Department of Frontier Sciences

Takeo Igarashi (Professor), Department of Computer Science

UNIVERSITY OF TOKYO PROJECT MANAGEMENT

Kensuke Hotta

Shohei Furuichi

Kosuke Nagata

Shuta Takagi

Shuntaro Nozawa

Iris Zhang

Déborah Lopez Lobato

Hadin Charbel

Haoran Xie

SECOND YEAR STUDENT TEAM

Alric Lee

Isaac Yoo

Ittidej Lirapirom

Luca Marulli

Moritz Münzenmaier

Pan Kalin

Victor Hugo Wido

FIRST YEAR STUDENT TEAM

Hirokazu Nakano Tei

Mika Kaibara Portugaise

Nathália Barros Abate Rotelli

Rūta Stankevičiūte

Tom Moss

Tyler Timothy McBeth

Veronika Smetanina

Xiaoke Chen

Yang Ao

Ziyi Wu

ADDITIONAL SUPPORT

Emi Shiraishi

Federico Cazzaniga

PHOTOGRAPHS

Toshihiko Kiuchi (Assistant Professor, University of Tokyo)

パビリオン公開 // PAVILION DISPLAY

12月5日(月)– 12月18日(日)// December 5 (Mon) – December 18 (Sun)

10:00 – 17:00

東京大学本郷キャンパス工学部1号館前広場

The University of Tokyo, Hongo Campus, Engineering Building #1 Plaza

パネル・模型展示 // PANEL AND PROCESS EXHIBITION

12月5日(月)– 12月17日(土)// December 5 (Mon) – December 17 (Sat)

平日と土曜日のみ // Weekdays and Saturdays only

07:00 – 18:00

(12月5日は13:00から) // (Open at 13:00 on December 5)

東京大学本郷キャンパス工学部 11 号館1階展示スペース(入場無料)

The University of Tokyo Hongo Campus, Engineering Building #11, 1F Exhibition Space (free entry)

主催: 東京大学建築学専攻 Advanced Design Studies(T—ADS)

PRODUCED BY: Advanced Design Studies, Department of Architecture, The University of Tokyo

企画: 東京大学建築学専攻 Digital Fabrication Lab(DFL)

鹿島建設株式会社

東京大学大学院情報理工学系研究科コンピュータ科学専攻 五十嵐健夫研究室

東京大学大学院新領域創成科学研究科社会文化環境学専攻 佐藤淳研究室

素材協力: 株式会社エコグリーン、株式会社東邦アーステック(順不同)

PLANNING:

Digital Fabrication Lab (DFL), Department of Architecture, The University of Tokyo

IN COLLABORATION WITH:

Kajima Corporation

Graduate School of Information Science and Technology, Department of Computer Science, Takeo Igarashi Laboratory

Graduate School of Frontier Sciences, Department Socio-cultural Environmental Studies, Jun Sato Laboratory

MATERIALS PROVIDED BY:

Eco Green, Toho EarthTech (in random order)

東京大学建築学専攻Digital Fabrication Lab(DFL)では、建築施工におけるデジタル技術の活用をテーマに、毎年実験的なパビリオンを制作しています。単に技術による自動化や高度化を目指すのではなく、そこに「人間が関わること」の可能性を探る実証の場として、これまで「人間と機械が融合した3Dプリンター」(2014年STIKパビリオン)や「巨大3Dペン」(2015年TOCAパビリオン)を建築スケールで再現してきました。

本年Computational Clayプロジェクトでは「人間が関わること」をより一層推し進め、個性としての身体パフォーマンスを建築表現に反映させるため、人の動きと素材と関係に着目したユニークなパネル加工システムを開発しました。

Every year in the University of Tokyo’s Digital Fabrication Lab (DFL), digital fabrication technologies are used to produce an experimental pavilion project. The aim, rather than being simply to achieve automation or precision through use of such technologies, is to explore the potentials for human and machine collaboration. Past projects have focused on fusions between humans and machines through the use of 3D printers: the 2014 STIK Pavilion explored this theme through guided aggregation, and the 2015 TOCA Pavilion by using humans as a parameter along with an oversized 3D pen.

This year, in the Computational Clay Pavilion, we advance the role of the human in construction one step further, examining how an individual’s capabilities and performance can be expressed in an architectural output. We have developed a unique panelized construction system wherein the movements of humans and their relationship to the material are explored.

The 2015 Digital Fabrication Lab project, TOCA (Tool Operated Choreographed Architecture) explored the potentials of human-machine collaboration in a manner that expanded on the knowledge acquired in the 2014 STIK Pavilion project. The research and development of the TOCA project sought to utilize the adaptability and creativity of humans, and combine it with the precision and efficiency of machinery. The resulting pavilion utilized a scanning and guiding system to support human users on-site, a material used to extrude components (foam), a handheld “smart” tool to dispense the material, and a geometric form which iteratively optimized through use of a feedback system that integrated human error. The pavilion project, which began with a digitally-defined target model, was constructed on-site by teams of users, who sprayed components by hand. The results of the work were scanned and analyzed, and an updated digital model was defined and indicated to users for the next layer of the project. In this manner, any “errors” introduced throughout the spraying process were integrated into subsequent construction steps. The final pavilion represents the accumulation and integration of these errors. The project was made possible through cross-disciplinary collaboration; structural engineering, architecture, and computer science laboratories contributed to realizing the technologies and the final output.

Project Credits

University of Tokyo Staff

Yusuke Obuchi (Associate Professor), Department of Architecture

Jun Sato (Professor), Department of Frontier Sciences

Takeo Igarashi (Professor), Department of Computer Science

Kaz Yoneda (Research Assistant), Department of Architecture

Kosuke Nagata (Technical Advisor), Computer Science

Kensuke Hotta (Course Assistant), Department of Architecture

Mika Araki (Researcher), Department of Frontier Sciences

Yosuke Takami (Technical Assistant), Department of Computer Science

Students

Gilang Arenza

Hadin Charbel

Ann-Kristin Crusius

Jiang Lai

Samuel Eugene Lalo

Deborah Lopez Lobato

Yuanfang Lu

Ratnar Sam

Pitchawut Virutamawongse

Ying Xu

Jan Vranovsky

Akane Imai

Pan Kalin

Yi Dong Alric Lee

Ittidej Lirapirom

Kenneth Larssen Lonning

Luca Maruli

Moritz Munzenmaier

Masatoshi Nishizato

Victor Hugo Wido

Christopher Wilkens

Li Xu

Isaac Sekjoon Yoo

Yihan Zhang

Sponsor

Takenaka

Photographer

Jan Vranovsky

Design Team:

The University of Tokyo teaching staff: Yusuke Obuchi, Toshikatsu Kiuchi, So Sugita, Hironori Yoshida, Kosuke Nagata, Kaz Yoneda

The University of Tokyo students: Kevin Clement, Minjie Xu, Fawad Osman, Qiaomu Jin, Ornchuma Saraya, Benjamin Berwick, Anders Rod, Yanli Xiong, Gilang Arenza Judinaputra, Pitchawut Virutamawongse, Samuel Aaron Eugene Lalo, Rossina Shatarova, Ratnar Sam, Ying Xu, Deborah Lopez, Hadin Habib Charbel, Ann-Kristin Crusius, Jiang Lai, Yuanfang Lu, Alexandra Karlsson, Jan Vranovsky, Mariko Mori

Completion date: November 2014

Digital Fabrication Lab Pavilion, 2014

Design Team:

The University of Tokyo teaching staff: Yusuke Obuchi, Toshikatsu Kiuchi, So Sugita, Hironori Yoshida, Kosuke Nagata, Kaz Yoneda

The University of Tokyo students: Kevin Clement, Minjie Xu, Fawad Osman, Qiaomu Jin, Ornchuma Saraya, Benjamin Berwick, Anders Rod, Yanli Xiong, Gilang Arenza Judinaputra, Pitchawut Virutamawongse, Samuel Aaron Eugene Lalo, Rossina Shatarova, Ratnar Sam, Ying Xu, Deborah Lopez, Hadin Habib Charbel, Ann-Kristin Crusius, Jiang Lai, Yuanfang Lu, Alexandra Karlsson, Jan Vranovsky, Mariko Mori

Shimizu Corporation: Kazuhide Sakai, Takeya Sato, Hiroyuki Ogura, Hideki Umeyama, Kiichiro Tanno, Zaita Hironori, Syunsuke Igarashi, Masahiro Indo, Keigo Takeuchi, and Shimiz Kiba Wood Workshop

Structural engineer: Jun Sato, Mika Araki, Masaaki Miki

Department of Socio-Cultural Environmental Studies / Graduate School of Frontier Sciences

Guidance System: Prof. Takeo Igarashi, Yosuke Takami

Department of Computer Science / Graduate School of Information Science and Technology

Design Phase: October 2013 – March 2014

Design development, fabrication & construction: April – November 2014

Completion date: November 2014

Digital Fabrication Lab Pavilion, 2013

Design Team:

The University of Tokyo teaching staff: Yusuke Obuchi, Toshikatsu Kiuchi, So Sugita, Hironori Yoshida

The University of Tokyo students: Christopher Sjoberg, Yeonsang Shin, Miguel Puig, Zhang Ye, Ana Luisa Soares, Ma Sushuang, Tong Shan, Andrea Trajkovska, Quangtuan Ta, Wei Wang, Anders Rod, Benjamin Berwick, Qiaomu Jin, Fawad Osman, Yanli Xiong, Andrea Bagniewski, Kevin Clement, Ornchuma Saraya, Minjie Xu

Obayashi Corporation: Tomoo Yamamoto, Kenichi Misu, Gendai Ono, Yasuo Ichii, Keisuke Fujiwara, Shunsuke Niwa, Tatsuji Kimura, Masaru Emura, Taiki Byakuno, Takahide Okamoto

Structural engineer: Jun Sato

Fabrication of components: Tsukasa Takenaka (AnS Studio)

Construction: Multibuilder

Fabrication: Togari Kogyo

Structure: Freeform Surface Tensegrity Structure

Specifications:

Compressive components: stainless steel plates with 0.5 mm / 0.8 mm / 1.2 mm / 1.5 mm thickness

Tension cables: stainless steel cables in 3 mm diameter

Base ring: stainless steel pipe in 48mm diameter

Foundation: precast concrete blocks

Furniture: painted plywood

Weight: 1.5 t (upper structure in stainless steel), 1 t (concrete foundation)

Design Phase: October 2012 – March 2013

Design development, fabrication & construction: April – November 2013

Completion date: 24 November 2013

Circle Pack Pavilion

Project Team : Taichi Kuma, Colin Xuhao Lin, Mickey Kyaw Htoo, Wang Chong, Guillaume Dumont, Wang Lin

with Olesia Biloborodko, Yuta Ito, Ana Ilic, Yasemin Sahiner, Maria Larsson, Dejan Zoran Mojic, Shuang Li, Dasom Lee, Ana Luisa Soares, Zhang Ye, Tong Shan, Shin Yeonsang, Miguel Puig, Christopher Sjoberg, Ma Sushuang, Laura Miguelanez, Andrea Trajkovska

Yusuke Obuchi, Associate Professor

Jun Sato, Associate Professor

Toshikatsu Kiuchi, Course Assistant

So Sugita, Course Assistant

Minimal Surface Pavilion

Project Team : Jeep Prinya Narongthanarath, Taichi Kuma, Akinori Hamada, Deli Zhao, Olesia Biloborodko, Colin Lin Xuhao, Chong Wang, Mickey Htoo, Yasemin Sahiner, Shuang Li, Maria Larsson, Ana Ilic, Guillaume Dumont, Dasom Lee, Yuta Ito, Ryo Saito, Risa Kagami, Lin Wang, Dana Milea

Yusuke Obuchi, Associate Professor

Kengo Kuma, Professor

Jun Sato, Associate Professor

Toshikatsu Kiuchi, Course Assistant

Featured at 2011 Tokyo Designers’ Week.