Collaborative Constructions

Kizuki-au、築き合う– Collaborative Constructions

Our globalised societies have entered a new phase. The pandemic has revealed how our communities are intricately linked beyond borders and how mutually dependent we are in an evermore fragile world. Meanwhile, the popularization of online communication demonstrates how technology helps us re-connect even in forced isolation; we could talk to anyone, anywhere, anytime. In this emerging order, how can architecture reimagine its tradition and role in society?

Collaborative Constructions investigates a new practice of architecture based on the creative, innovative and personal use of technology. The projects by Gramazio Kohler Research at ETH Zurich, and T_ADS Obuchi Lab of the University of Tokyo engage in a collaboration seeking architectural strategies to relate nature and humanity through technology; human-robot collaborations exemplify how we can engage with the past while looking ahead.

The project reimagines Tokoname with its post-industrial legacy, through an extended notion of empathy: its people, traditions, history, environment and culture are intertwined and made tangible through digital fabrication. Architecture becomes an expression of being alive.

The project is an initiative of the Embassy of Switzerland in Japan, ETH Zurich and the University of Tokyo, in collaboration with Shimizu Corp. It is part of the Vitality.Swiss program.

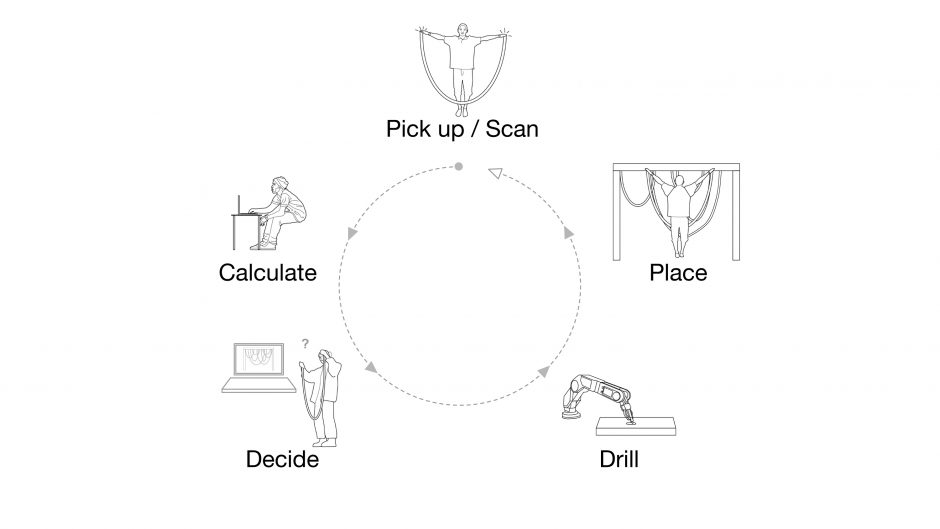

Participatory Shape Generation

Each person makes a uniquely defined shape of pottery chain by holding it with different physiques and strengths reflecting their individuality.

Real-time Optimization

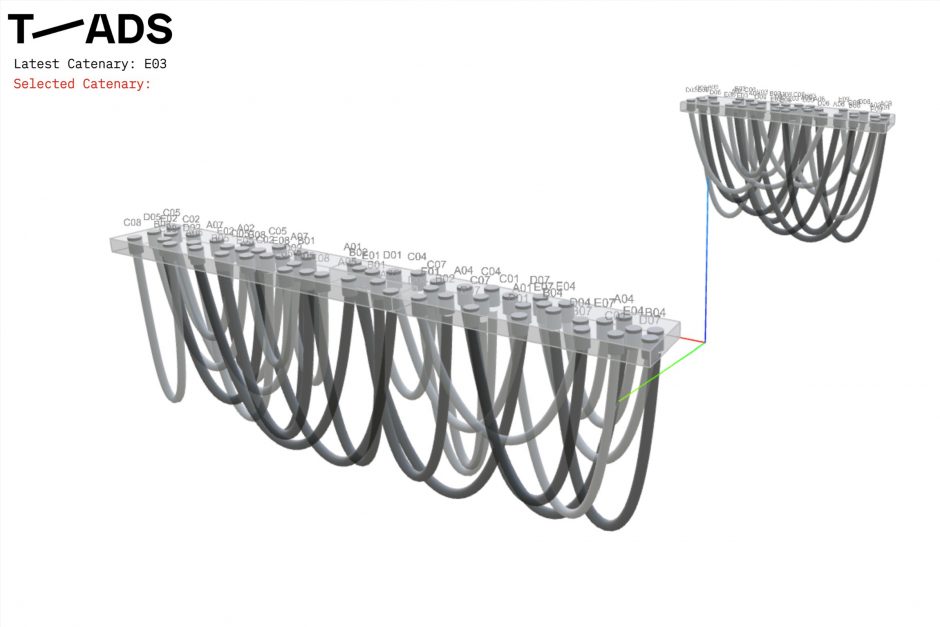

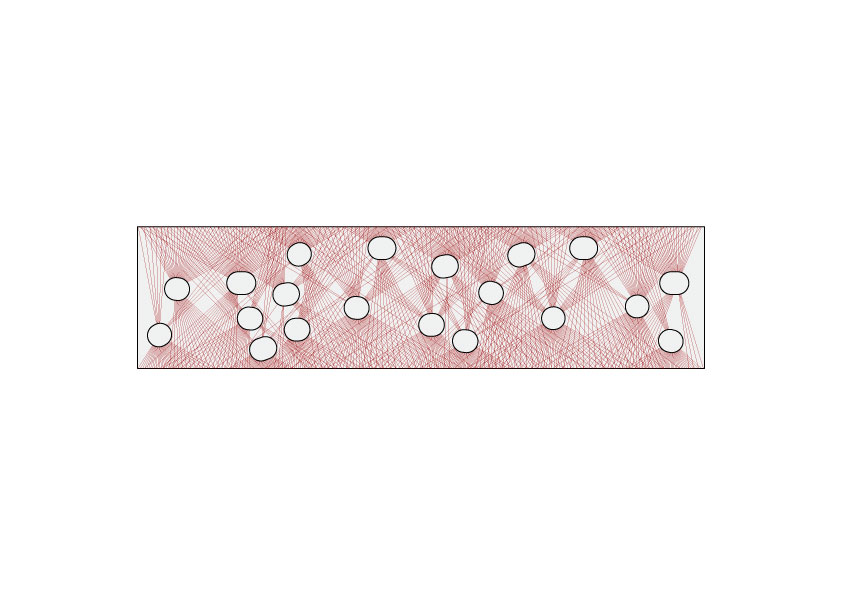

The heart of the project is the fabrication of the hanging pottery chains. While the pattern appears to be random at first glance, its generation requires an intricate algorithm, an algorithm that brings humans and machines together.

Robotic Drilling

“Collaborative Constructions” combines elements of traditional architectural construction, culture, and natural materials with modern digital technologies such as computational design and robotics fabrication.

Collaborative Constructions

Process Chronology

Human Scaled Participatory Shape Generation

The pottery chains are created by a series of feedback processes between a person and a robot. The pottery chains are created by a series of feedback processes between a person and a robot. Sensors are placed on each subject’s hand so that the information-gathering process is as natural as possible.

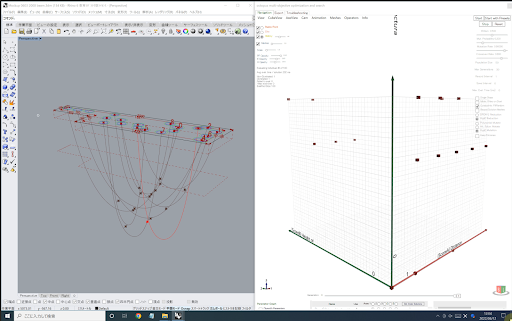

Real-time Optimization Controlling Design Outcome

Optimization Criteria

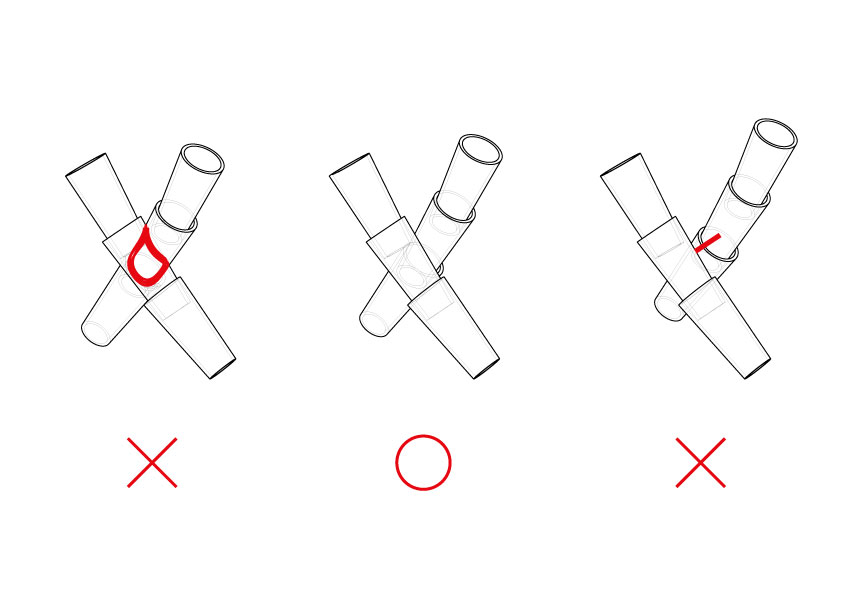

Tangential Connections

Distance between catenaries should be within a certain domain to avoid intersection, but meanwhile should allow to be tied together.

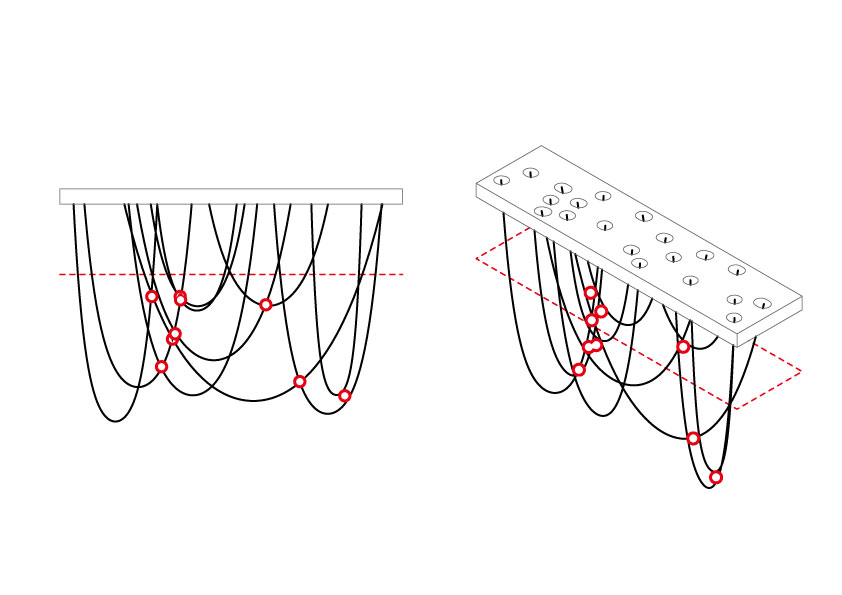

Intersection Height

Position of connections should be far away enough from the beam to ensure structural stability.

Structural Continuity

Each drilling point should have direct route for force transmission to the edge of the beam.

Human Evaluation / Decision

Searching for Optimized Placement Options

Human Evaluation / Decision

Real-time decisions controlling Design Outcome

Robotic Drilling and Assembly

Credits:

University of Tokyo Obuchi Laboratory

Yusuke Obuchi

Shuta Takagi, Yusuke Komate

2021-2022

Alex Orsholits, Zhou Li, Cheng Zhe Zhu, Kritika Dhupar

2020-2021

Alex Orsholits, Annette Choi, Zhou Li

2019-2020

Alex Orsholits, Aungsoe Pyaezone, Boon Hau Lim, Campbell Meredith Argenzio, Dominika Demlova, Hao Li, Ke Zhou, Surjyatapa Ray Choudhury, Yiyuan Qian, Yucheng Zeng, Annette Choi, Zhou Li

Digital Fabrication Research Collaborator:

Shimizu Corporation Construction Technology Division

Construction:

Shimizu Corporation

Mist Design:

Panasonic Holdings Corporation

Manufacturing Innovation Division

Structural Design:

University of Tokyo Jun Sato Laboratory

Pottery Production Advisor:

LIXIL Corporation

INAX Museums Cultural Promotion Department

Pottery Artist:

Daisuke Tominoto, Sachiko Iketani